Water Test Stands:

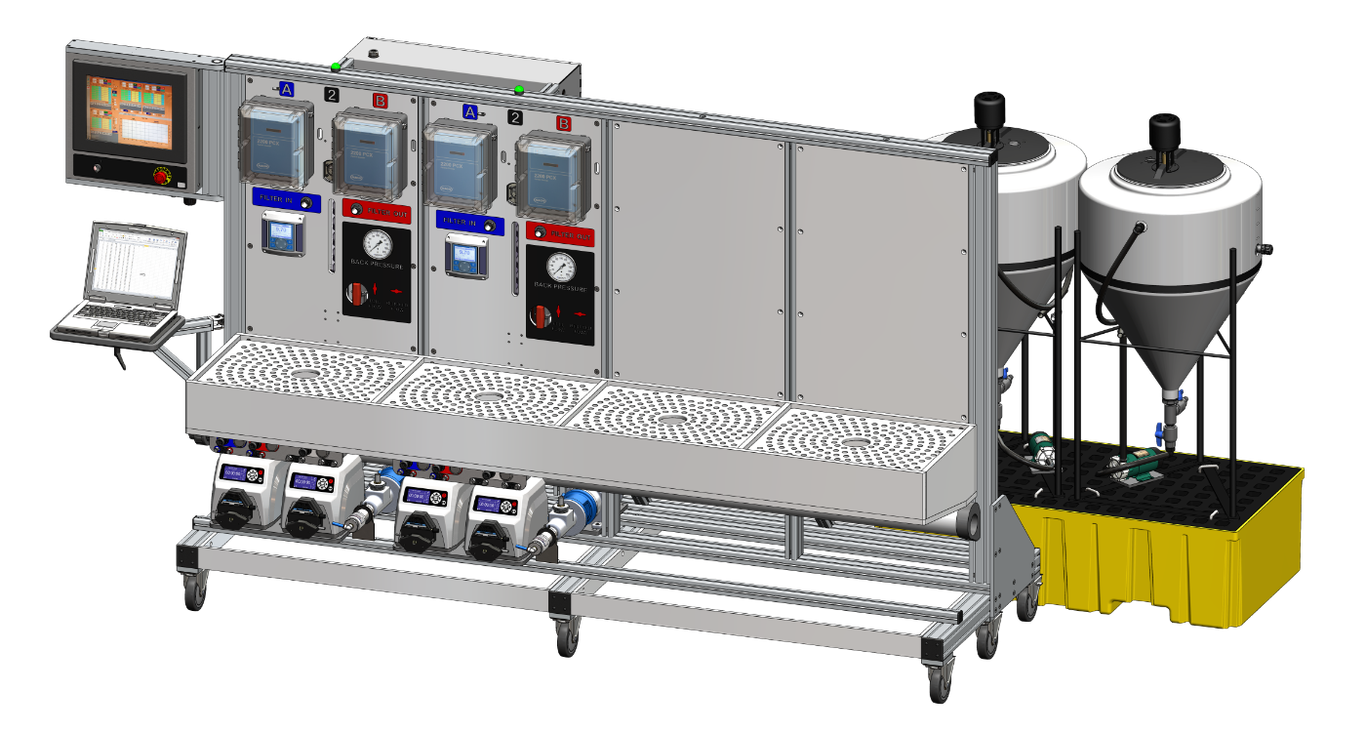

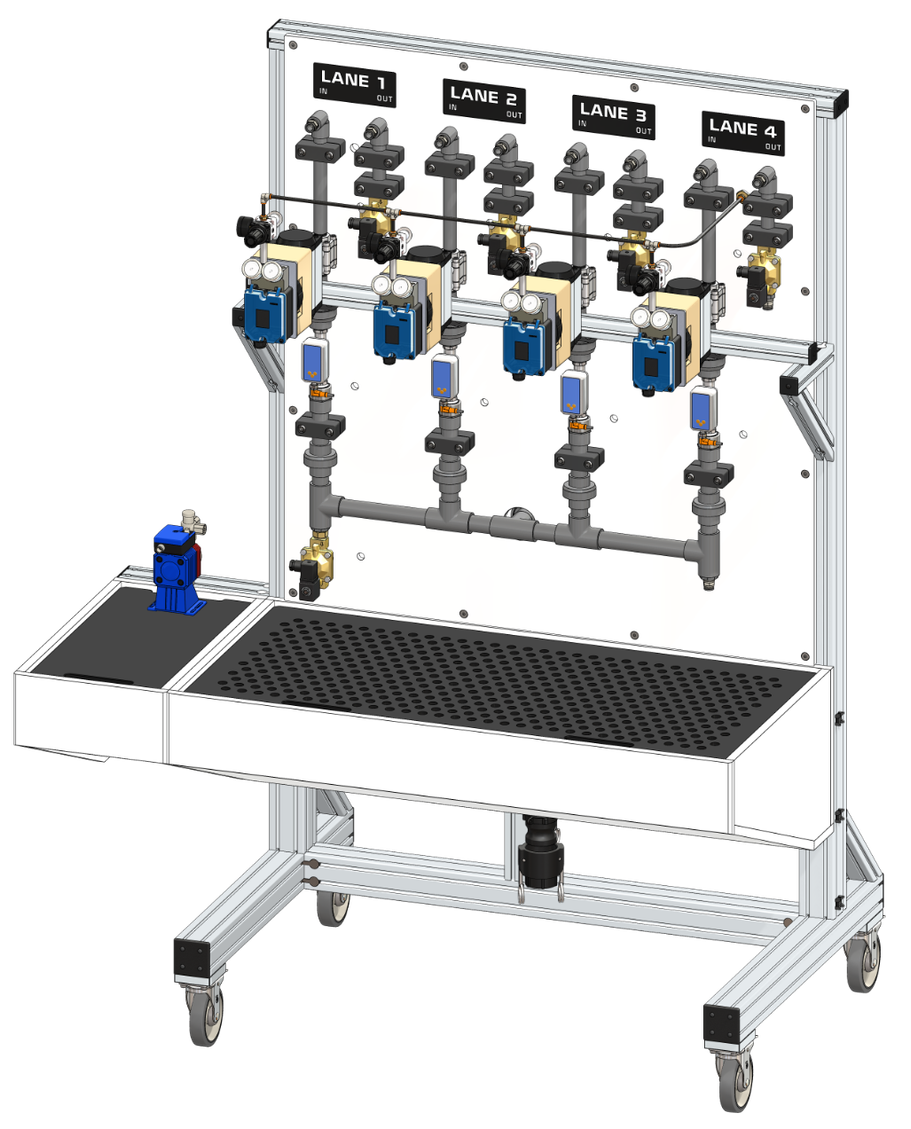

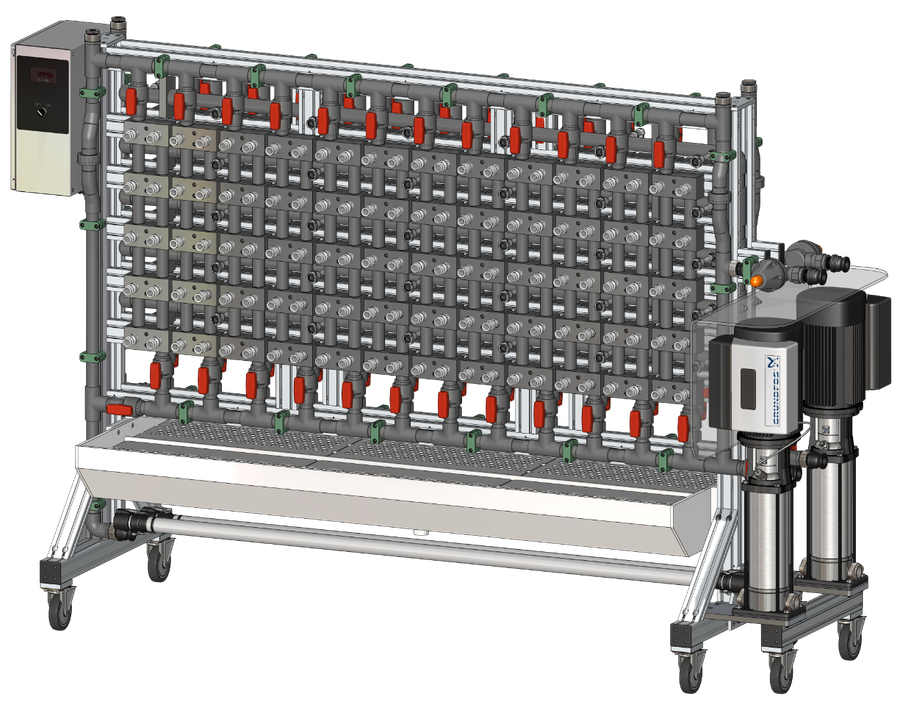

Fritze Dezein designs and manufactures laboratory equipment for water treatment testing that creates and directs a test water to pass through a treatment device to determine the performance envelope of the treatment process. This test water (influent) is directed to one or more water treatment devices according to a dosing schedule. The treated water (effluent) is then measured to determine the efficacy and capacity to treat the water. Examples of Test Stand types include:

- Chemical Injection – The creation of a test water solution using precision metering of a chemical concentrate into a stream of clean water to a known concentration. Examples of test waters containing chemical contaminates include:

- Chlorine

- Ammonia

- VOC’s

- Colored dyes

- Metallic solutions such as lead and hexavalent chromium

- Minerals such as calcium and magnesium salts

These chemical contaminants are typically prepared in a concentrated form which can then be injected into a stream of water and blended with a static mixer to produce a large quantity of influent test water. This influent test water is then directed through control valves into test devices. The influent test water can have its pressure, flow rate, and temperature controlled and measured while it is dosed through treatment devices according to a schedule of flow and rest intervals until a targeted capacity is reached.

- Particulate Injection – The creation of a test water solution using precision metering of a particulates into a stream of water to a known concentration. Examples of test waters containing particulate contaminates are:

- AC Fine Test Dust (turbidity)

- Micro-sphere latex or polystyrene (cryptosporidium cyst surrogate)

These particulate contaminants are typically added as dry powders into a tank and blended to keep the particles in a concentrated suspension. A specialized pump then draws the concentrated slurry and injects it into a stream of water to a known concentration and blended with a static mixer to produce a large quantity of influent test water. This influent test water is then directed through control valves into test devices. The influent test water can have its pressure, flow rate, and temperature controlled and measured while it is dosed through treatment devices according to a schedule of flow and rest intervals until a targeted capacity is reached.

- Gas Injection – The creation of a gasified water solution using a variety of methods including sparging, membrane diffusion, electrolysis, and pressure absorption. Gasified waters can be used for many water treatments processes such as:

- Oxygen for reducing contaminants such as iron removal, cleaning, or disinfection

- Oxygen for plant growth and aquaculture and organic decomposition

- Oxygen and hydrogen for producing enhanced waters, medical uses, and cleaning

- Nitrogen for beverages

Some of the contaminates can be monitored in real-time using laser particle counters or other on-line pH, chlorine, ORP, temperature, colorimetric, and conductivity sensors.

Other contaminants require samples to be drawn for subsequent analysis using ICP-MS or other wet chemistry analysis offline.

Fritze Dezein has built a variety of Flow Stands using peristaltic pumps, vertical multistage centrifugal pumps, progressing cavity pumps, magnetic drive pumps, and diaphragm dosing pumps to blend water and chemicals for the production of an influent test water. Various flow meters such as turbine, paddle-wheel, magnetic, thermal, and vortex can be selected to meet the desired needs for accuracy and resolution. Control valves such as actuated ball valves, pinch valves, angle seat valves, solenoid valves, and servo operated valves can be used to control the flow through the water treatment devices.

Flow stands are typically constructed on an extruded aluminum framework with stainless fasteners and casters. A polypropylene tub with removable grates that catch spillage and provides a surface to hold test devices. Polypropylene back boards are used to mount the instrumentation and piping. Often times, a variety of pre-filtration elements are used to clean the incoming city water supply to create the clean water before injecting the contaminants. Water that has been injected with the various contaminants and chemicals can be cleaned through a series of other post-treatment filters before being discharged into the city sewer system. Various pumps and containers can be fitted to lower shelving and side shelves as desired. We can also provide full stainless steel stands as desired.

The entire flow stand is automated by a PLC controller and can be programmed for a variety of schedules, concentrations, capacities etc.

Can we dezein a test stand for you?

Give us a call or send us an email! We are happy to design and manufacture a piece of test equipment to your exact specifications.