RFID PICK-PLACE:

Fritze Dezein has experience with specifying, designing, and integrating specialized equipment which can punch and handle RFID tags and then adhesively bond them to products.

We can work with the specialized equipment manufacturer and integrate the necessary tooling and controls for automation.

- Punching and Placing Equipment – Each application and RFID tag format requires specialized equipment to handle and separate the tags from the roll they are supplied on. We work with companies that handle this task and we can specify the machine and integrate it into a manufacturing assembly station.

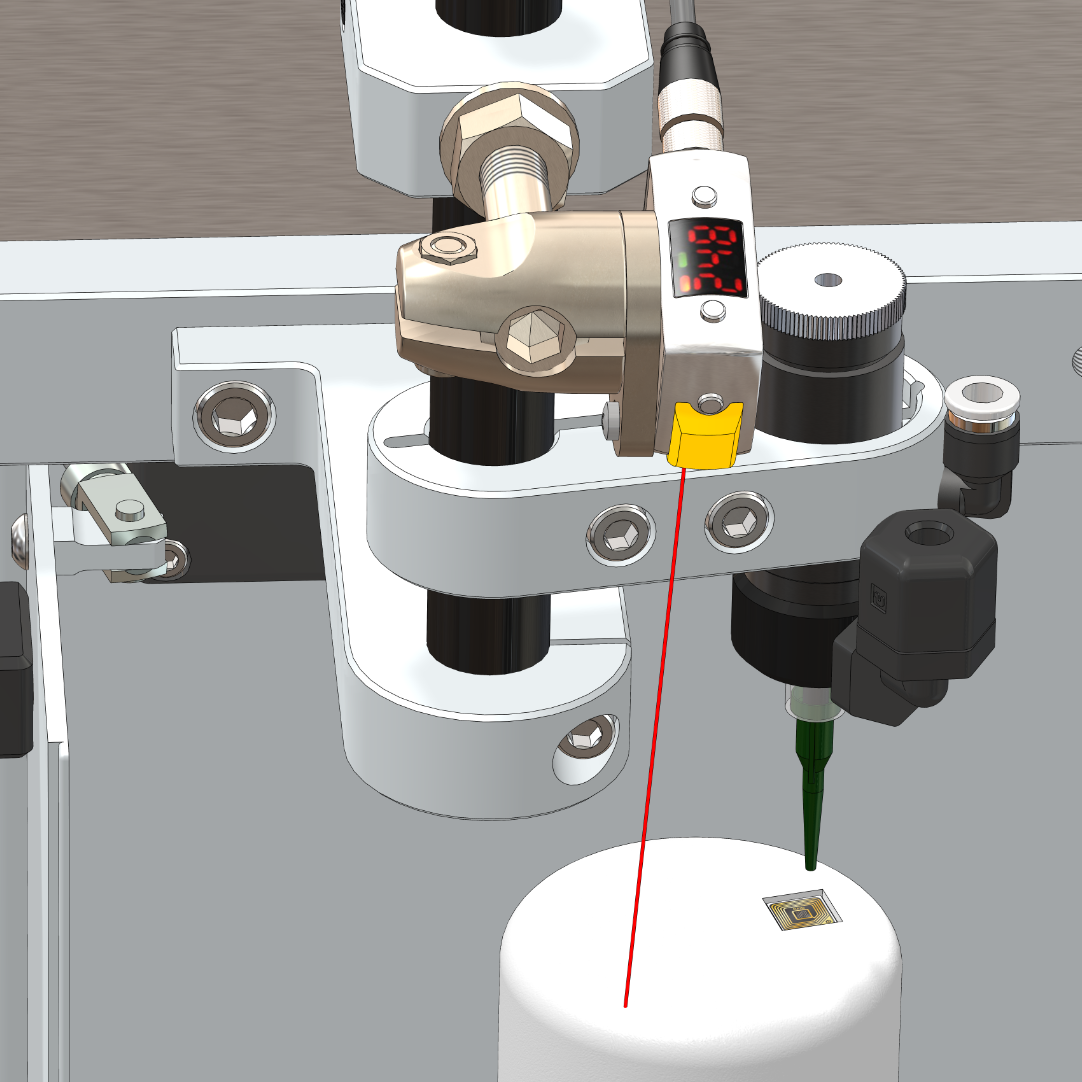

- Pick and Place Actuator – Each tag must be picked and placed onto the product. Some tags have pressure sensitive adhesive already, others require an application of adhesive. We can help select the adhesive and application equipment while handling the tags and placing them onto the products quickly and accurately.

- Adhesive Dispensing – The selection and integration of custom equipment to dispense the liquid adhesive onto the tag or product. Adhesives include 2-part epoxy and UV Cure.

Can we dezein a machine for you?

Give us a call or send us an email! We are happy to design and manufacture a piece of assembly equipment to your exact specifications.