UV Adhesive Dispensing and Curing:

Fritze Dezein has extensive experience with the design and development liquid dispensing equipment including involment with many patented technologies. We can integrate existing off-the-shelf dispensing equipment with custom tooling and fixtures or we can invent what is not readily available.

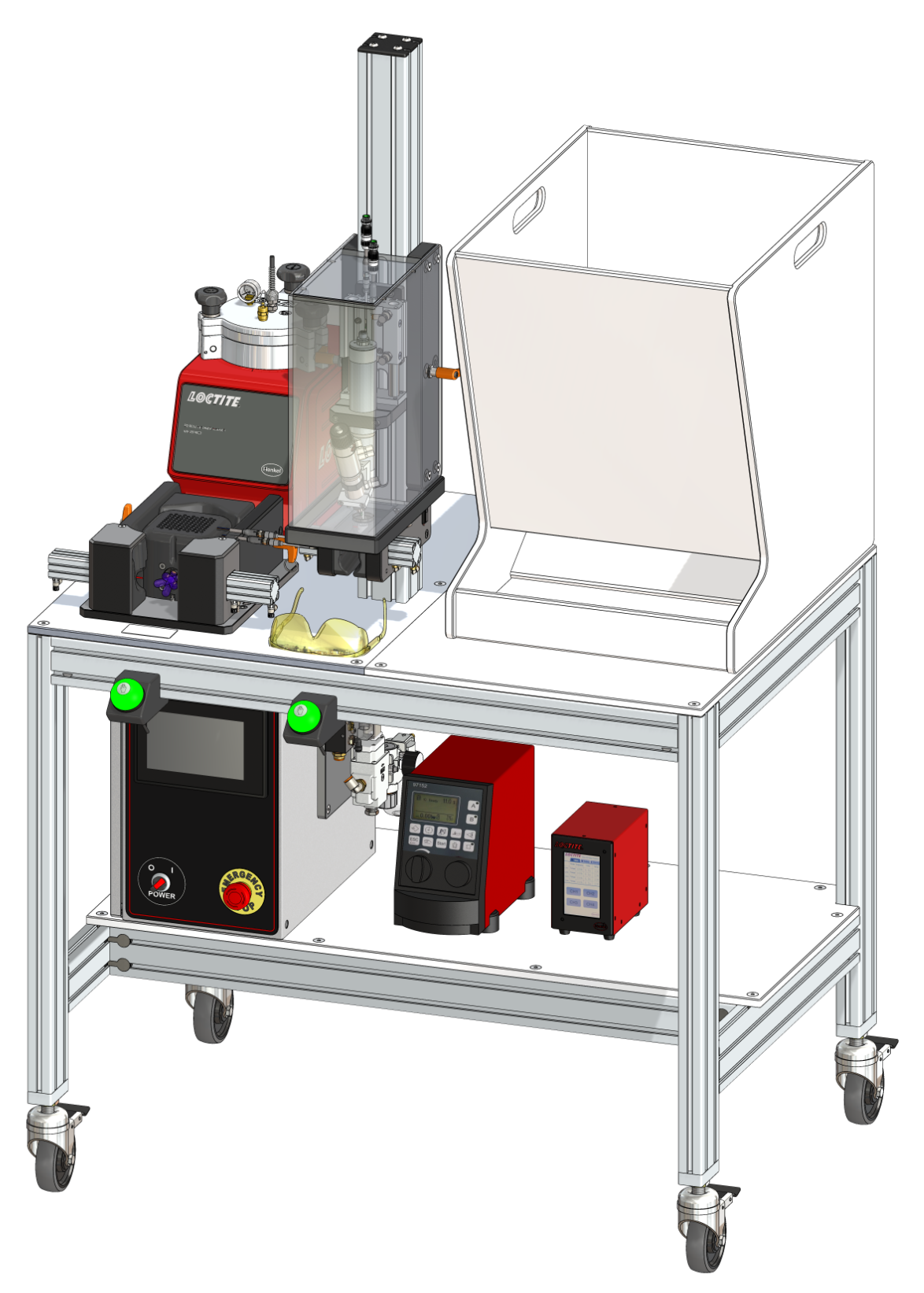

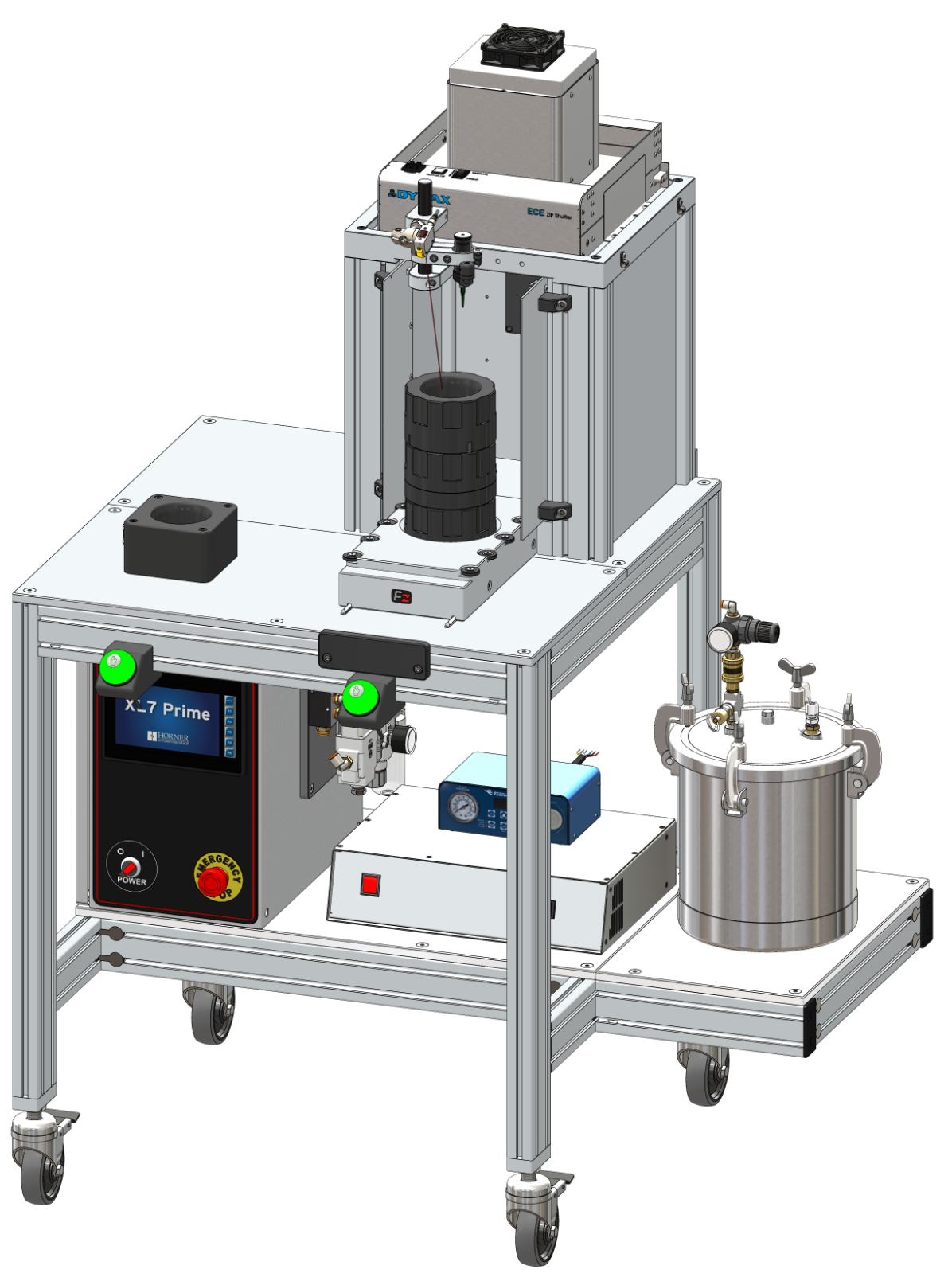

UV cured adhesives are used extensively in manufacturing today and we can integrated various manufacturers' dispensing equipment with associated UV lamps to cure the adhesive. The UV adhesive dispensing and curing systems can be mounted to operate alongside a conveyor system, or integrated into a semi-automatic fixturing system.

A typical system includes tooling to precisely locate and hold the part, a dispensing system with adhesive supply and dispensing valve, and UV lamp(s) with safety shielding to cure the adhesive. We work with leading equipment manufacturers such as Nordson, Fisnar, Loctite, and Dymax.

We offer many features in our custom designs:

- UV Protection enclosures – The glued part is placed within a protected enclosure to ensure operator safety while ultra violet light is used to cure the adhesive. The enclosure is fabricated from black polypropylene, aluminum, or other opaque material as desired.

- Safety Shielding – Viewing windows are made from certified polycarbonate or acrylic materials with filtering specific for the radiation wavelengths such as 365nm and 405nm wavelengths.

- Pressure Pots – When UV adhesive is supplied in bottles, we can recommend and integrate a pressure pot to supply adhesive to the dispensing valve.

- Automatic doors – We provide doors which open and close to safely guard the ultraviolet light from escaping the safety enclosure.

- Part, No-Part sensing – Each part can be proven to be in position before any adhesive is dispensed. We often use laser sensors to provide flexible and accurate sensing which are more immune to adhesive contamination.

- LED or UV Gas Discharge Lamps– We can help you choose the best UV light source for the application to reduce adhesive curing time and to focus the UV light exactly on the adhesive.

We integrate these systems with custom tooling into compact machines that are automated using PLC controls. Each machine is designed for ergonomic operator use with various safety systems which protect the operator during any unsafe conditions. An extruded aluminum frame with a CNC machined aluminum tooling plate provides a platform for machines and quick-change tooling system. Each job can be configured rapidly by swapping nests and fixtures which are magnetically attached and located in position.

Our controls are engineered for ergonomic operator use with touch buttons, easy to understand machine status via LED lamp colors, simple touch screen HMI, and fully automated recipe-selected programs. Our equipment is designed for long service life in harsh environments as we use plastic, aluminum and stainless steel where possible.

Fritze Dezein can help you determine what type of adhesive to use by researching, testing, and proving the strength and cycle times for your application. We work with the adhesive manufacture to specify the correct equipment and integrate it into a design for your specific application. We offer turn-key UV curing solutions for you.

Can we dezein a machine for you?

Give us a call or send us an email! We are happy to design and manufacture a piece of assembly equipment to your exact specifications.