Laser Marking and Decorating:

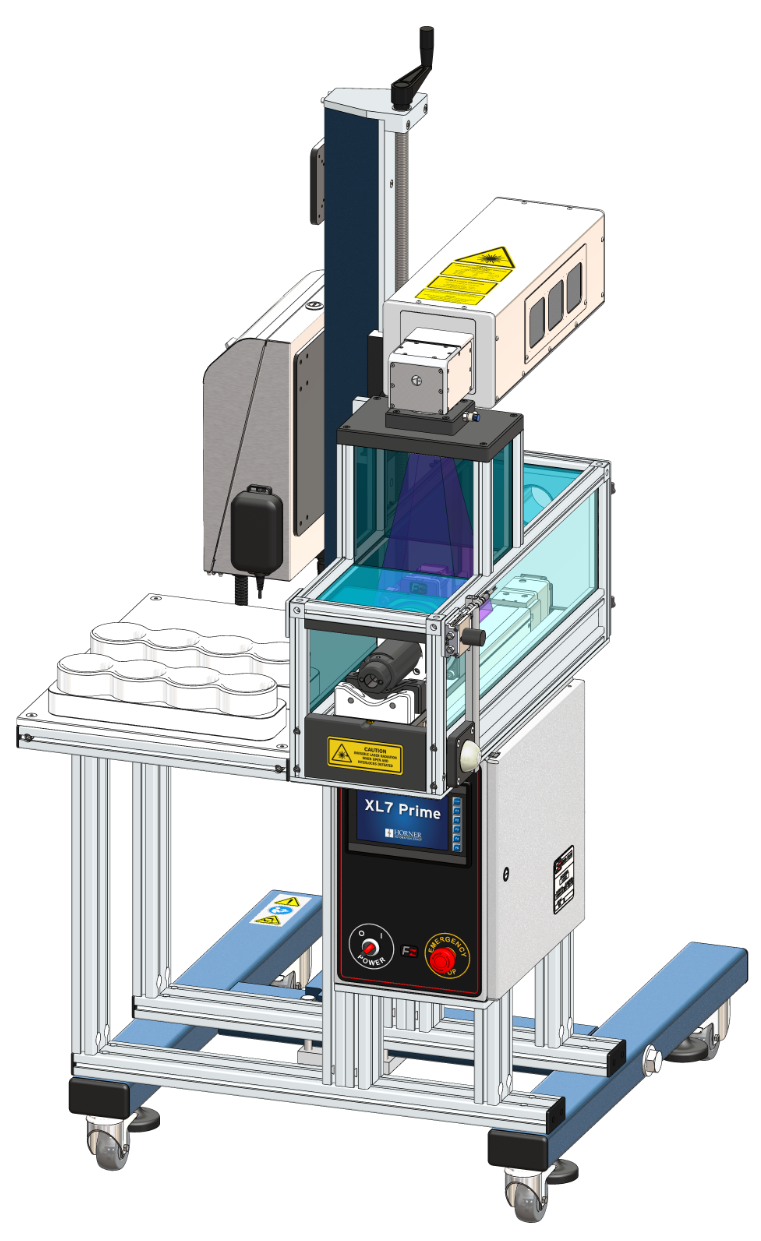

Fritze Dezein can build for you a variety of custom automated laser marking/decorating systems by integrating standard Laser Marking equipment into semi-automated part handling workstations or fully-automatic conveyor lines. We engineer each decorator system to shield personal from laser radiation by enclosing the part to be decorated inside a protected enclosure with suitable doors and optical shielding.

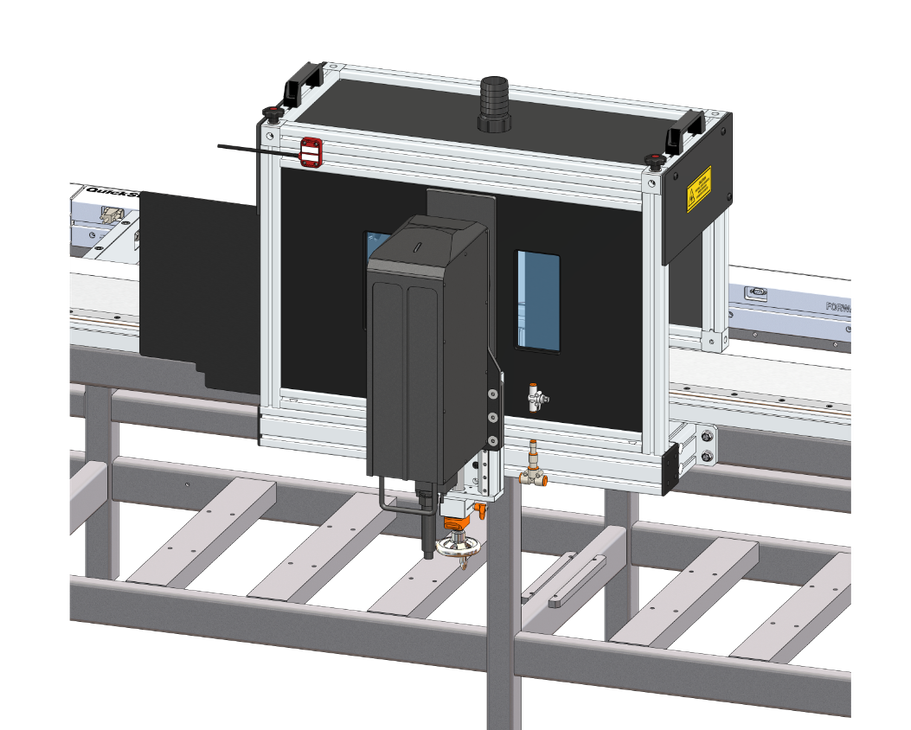

We integrate hybrid fiber lasers and UV lasers each selected for the application. The lasers can be mounted to operate alongside a conveyor system, or integrated into a semi-automatic fixturing system.

We develop equipment that can mark parts in many locations using precision positioning with linear and rotary actuators. Each part can have many different marks and decorations including text. At the push of a button, a series of laser marks can be placed anywhere on the parts surface.

We offer many features in our custom designs:

- Protection enclosures – The laser is fixtured to an enclosure that ensures stable and safe aiming of the laser light. The enclosure is fabricated from black polypropylene, aluminum, or other opaque material as desired. Laser backstop materials are chosen to survive continuous laser contact and prevent scattering.

- Safety Shielding – Viewing windows are made from certified polycarbonate or acrylic materials with filtering specific for the radiation wavelengths.

- Automatic doors – When tunnels lengths are not long enough, we provide doors which open and close automatically to safely guard the laser light from escaping the safety enclosure.

- Lens air purge – We can direct a source of clean air to protect the lens from long-term smoke contamination.

- Fume Extraction – We can integrate specialized fume extraction vacuums and provide ducting and venting features to keep the operators healthy and workplace clean.

- Part, No-Part sensing – We integrate safety systems which ensure that the part is in the correct position before it is decorated. We use optical and proximity sensors to allow permission to lase.

- Laser on the Fly – We can integrate the laser system to operate on a conveyor line to rapidly mark each part on the fly. A rotary encoder is sometimes used to track the exact speed of the moving parts so that the laser can accurately mark and decorate each part as it passes by.

Fritze Dezein can help you determine what type of laser to use by researching, testing, and proving the marking capability and cycle times for your application. We work with the laser manufacture to specify the correct equipment and integrate it into a design for your specific application. We offer turn-key laser marking solutions for you.

Can we dezein a machine for you?

Give us a call or send us an email! We are happy to design and manufacture a piece of assembly equipment to your exact specifications.