Carbon Block Manufacturing Equipment:

Fritze Dezein has experience in developing carbon block manufacturing technology by; handling and filling its powder ingredients, molding the carbon mixture, application of heat, cooling, sawing, measuring, and performance metrics.

- Powder Handling – We help specify the equipment needed for R&D scale operations and engineer systems by selecting manufactures that provide handling, conveying, mixing and filling equipment for your application. We design any custom equipment which connects the systems together and integrates the equipment into a functioning line.

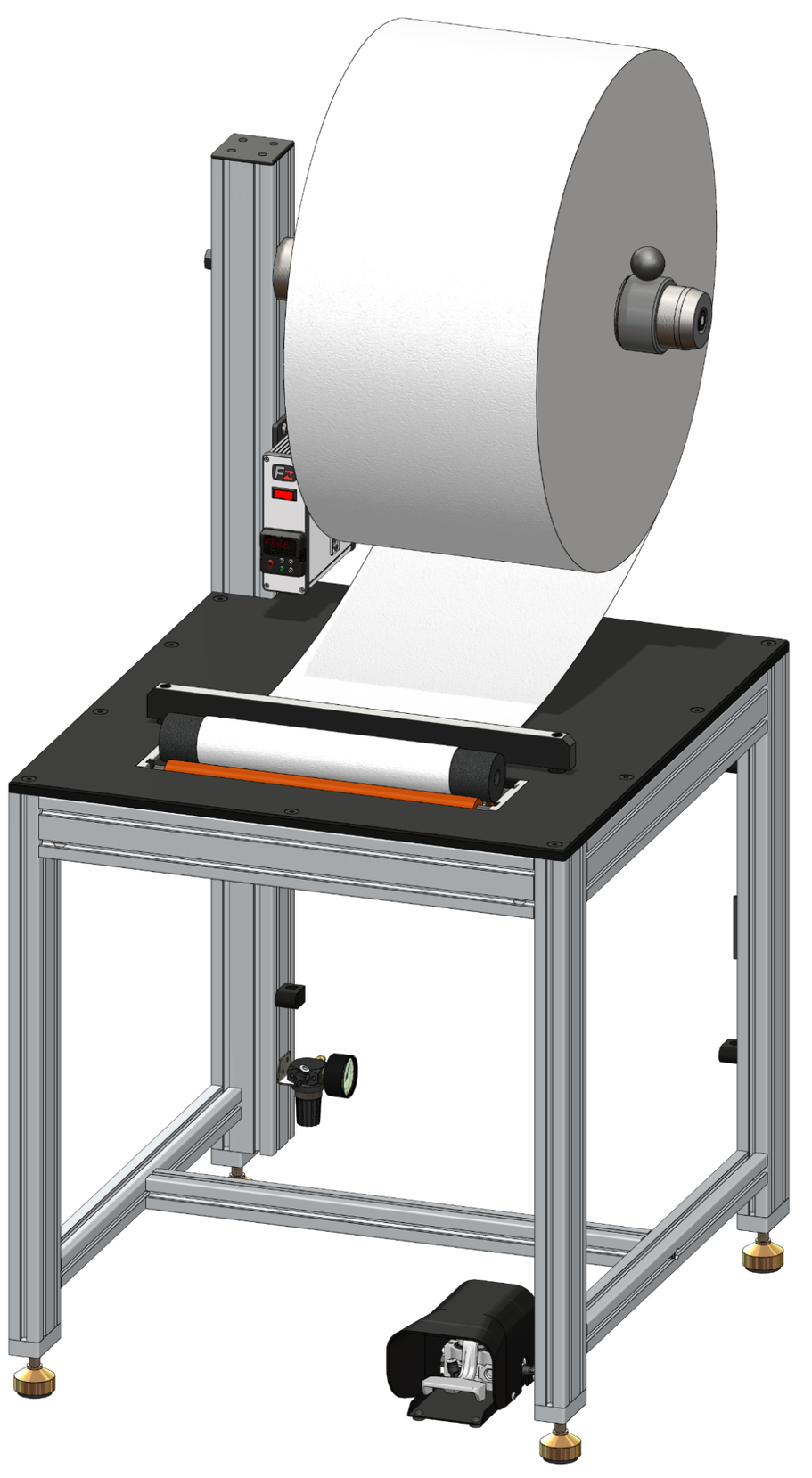

- Media Filling – We have designed and manufactured a variety of custom proprietary devices to load molds and prepare them for heating and machines to extract or eject carbon blocks after heating.

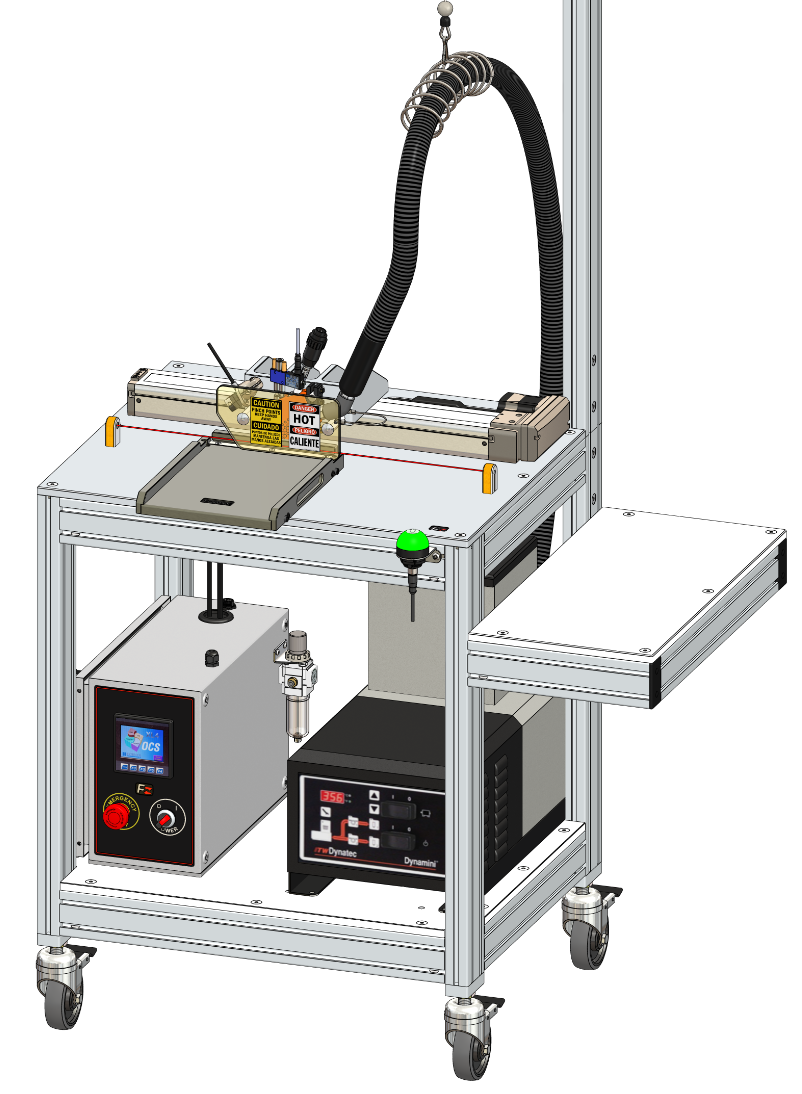

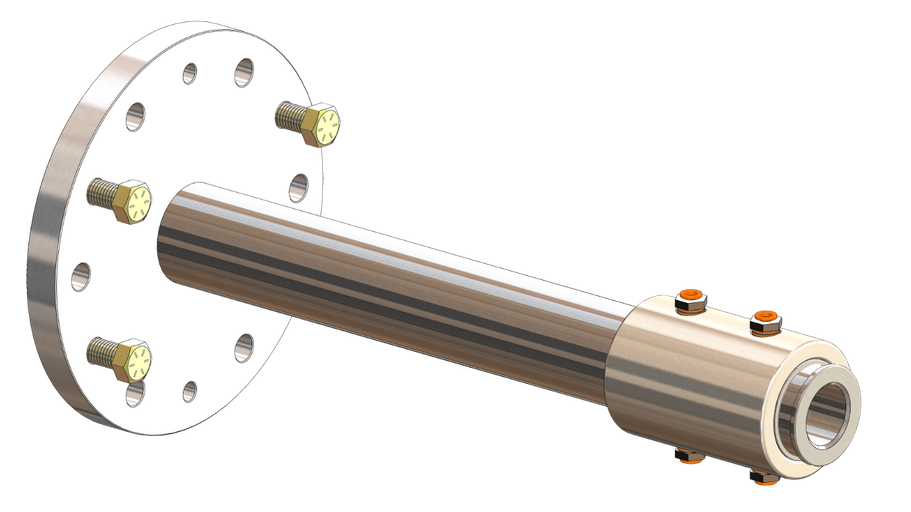

- Carbon Extrusion – We have designed and manufactured a variety of custom proprietary dies used to extrude carbon block media. Extrusion dies can be fabricated from stainless steel and have integral cooling systems. Other extrusion equipment can be fabricated with quartz tubes if the heat source is using electromagnetic radiation. We can offer continuous carbon spray cooling and drying equipment as well as pull-rolls, which provide precision pulling and twisting to provide the necessary tension/compression until the carbon is set.

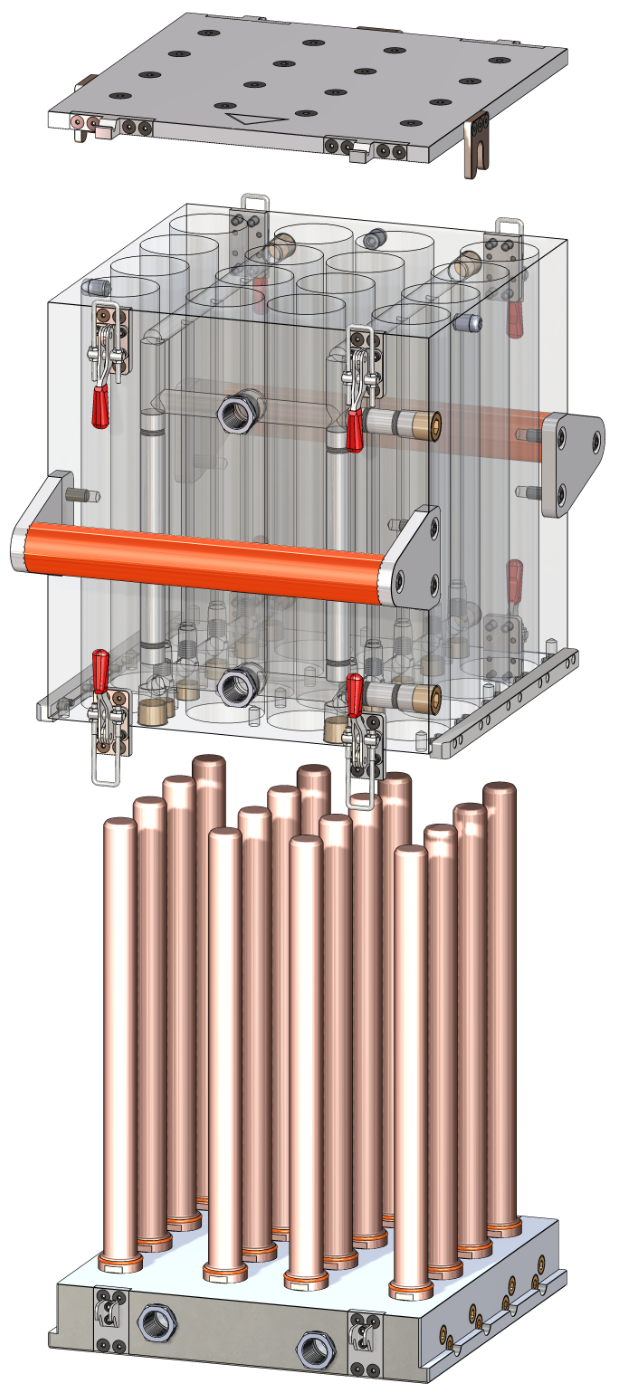

- Carbon Molds – We have pioneered special carbon block molds to rapidly heat and cool carbon powders sintering them into high-performance blocks. Molds can be electrically heated or steam heated and water cooled for rapid cycling.

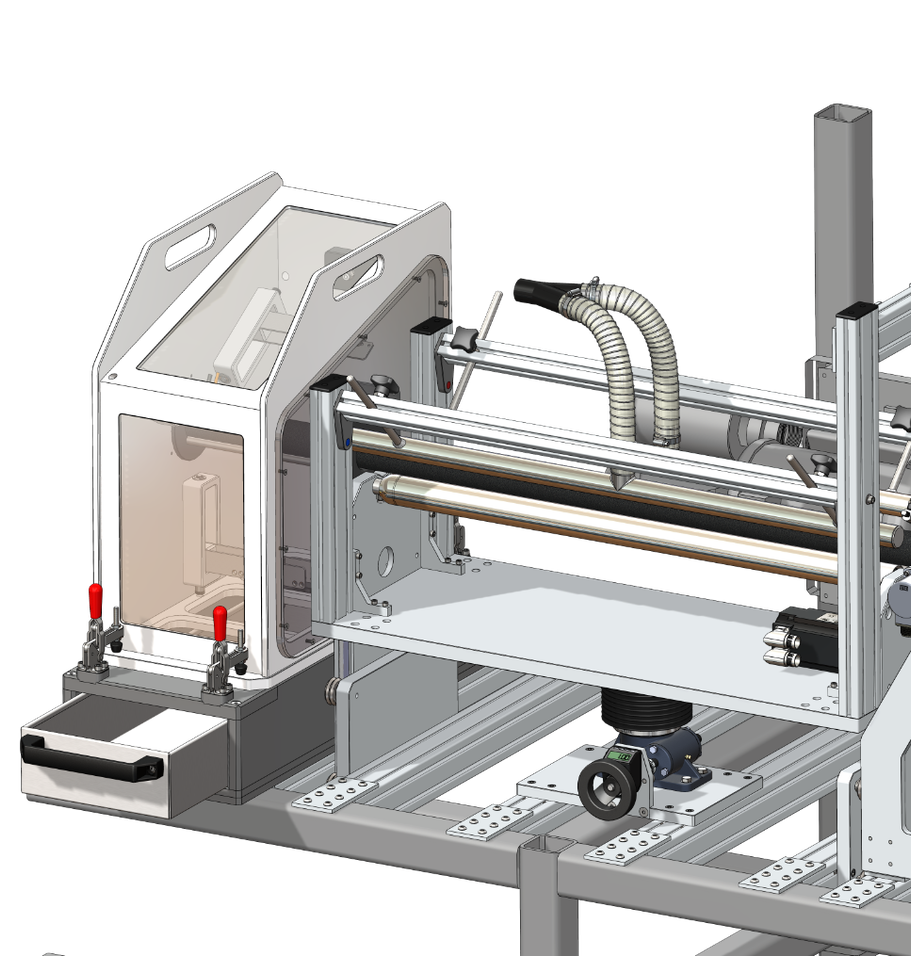

- Carbon Block Saws – We have developed high-speed equipment which can rapidly saw carbon block to exact lengths as desired. Equipment can process oversized blocks to exact length blocks in batches, or cut-to-length carbon blocks on the fly.

- Carbon Block Length Measurement – When using carbon block in automated filter production lines, it is often necessary to ensure that each carbon block is the correct size before it is glued into a filter cartridge. Fritze Dezein can employ its high-speed digital measuring heads to check each block before assembly and track the individual length variations for later analyses.

- Carbon Block Air Permeability Measurement – It is often necessary to ensure that each individual finished carbon block meets performance standards. Carbon blocks can be designed to filter out micron-sized particulates and microorganisms. In these applications, the rate of air permeability can be correlated to the effective carbon pore size. Fritze Dezein can build equipment which use an air-pulse pressure-decay to rapidly track production carbon block performance.

Can we dezein a machine for you?

Give us a call or send us an email! We are happy to design and manufacture a piece of assembly equipment to your exact specifications.