Leak Testing Machines:

Each production manufactured part or assembly often needs to be verified that they are all leak proof before they are used or sold. Leak testing is non-destructive and can verify that each individual part is fully tested and has passed this quality check. Leak testing is typically performed with clean dry air. We can use three basic methods to detect leaks:

- Pressure Decay – measurement of part's internal air pressure loss.

Fill part with compressed air to a target pressure, remove air source, and wait until system stabilizes. A first pressure is recorded at stabilization and is then compared to a second pressure taken at a later time. The change in part pressure is used to identify a leak rate. Pressure Decay is typically the lowest cost and fastest method.

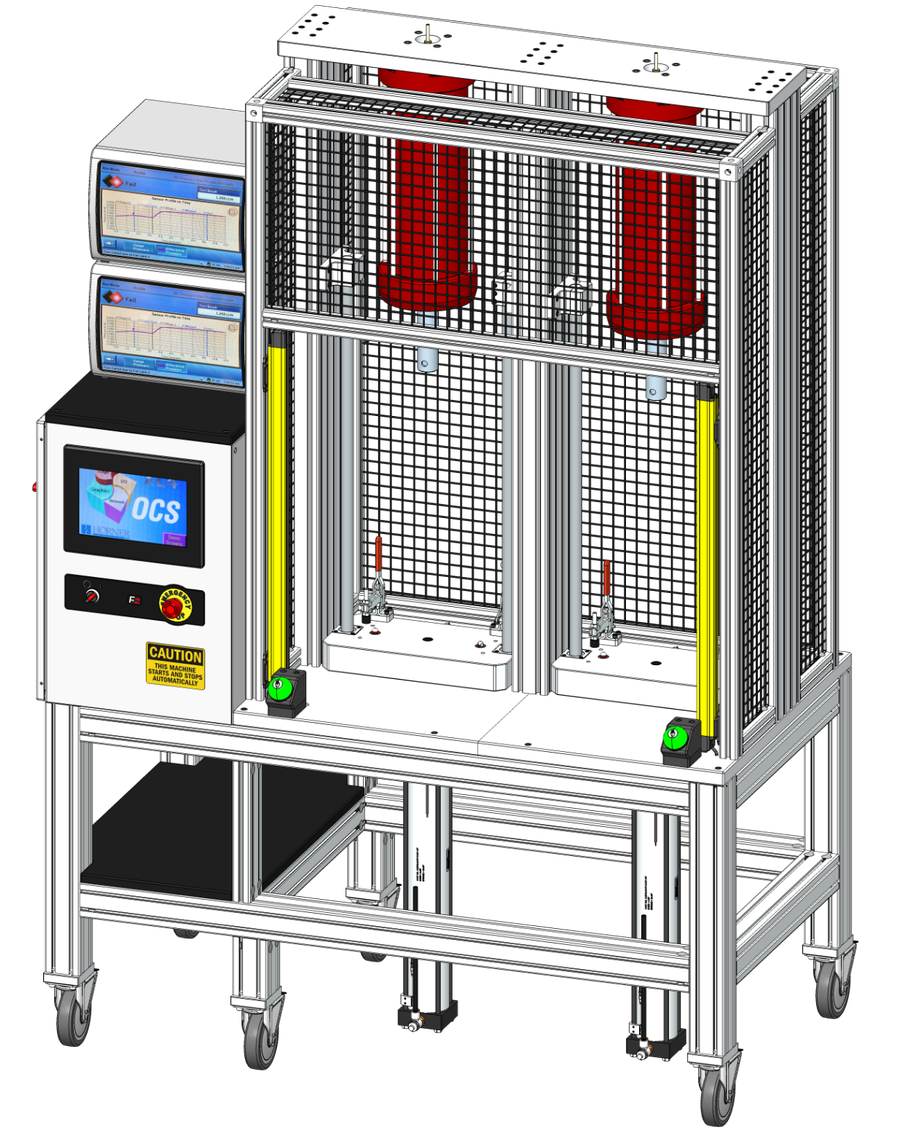

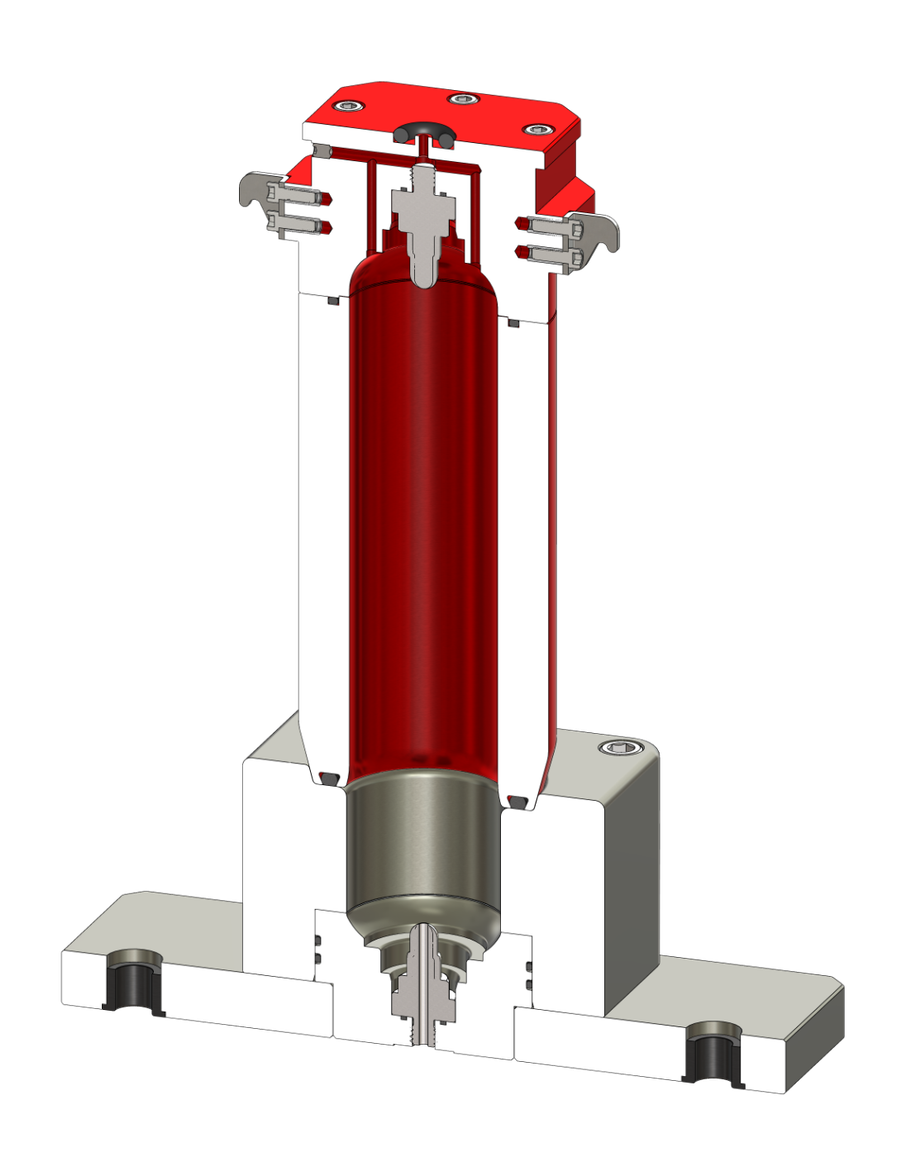

- Pressure Rise – measurement of air leaking from a part into a closed sealed chamber. Any air leaking from the part causes the chamber pressure to rise.

Enclose the part in a sealed chamber. Continually fill part with compressed air set to a target pressure. A first chamber pressure is recorded at stabilization and is then compared to a second chamber pressure taken at a later time. The rise in chamber pressure is used to identify a part leak rate. Pressure Rise is often used when the test part takes too long to stabilize its internal air pressure. Pressure rise works best when a close-fitting chamber and a differential pressure sensor are used. Water filters with carbon media are a perfect examples of parts tested with pressure rise technology.

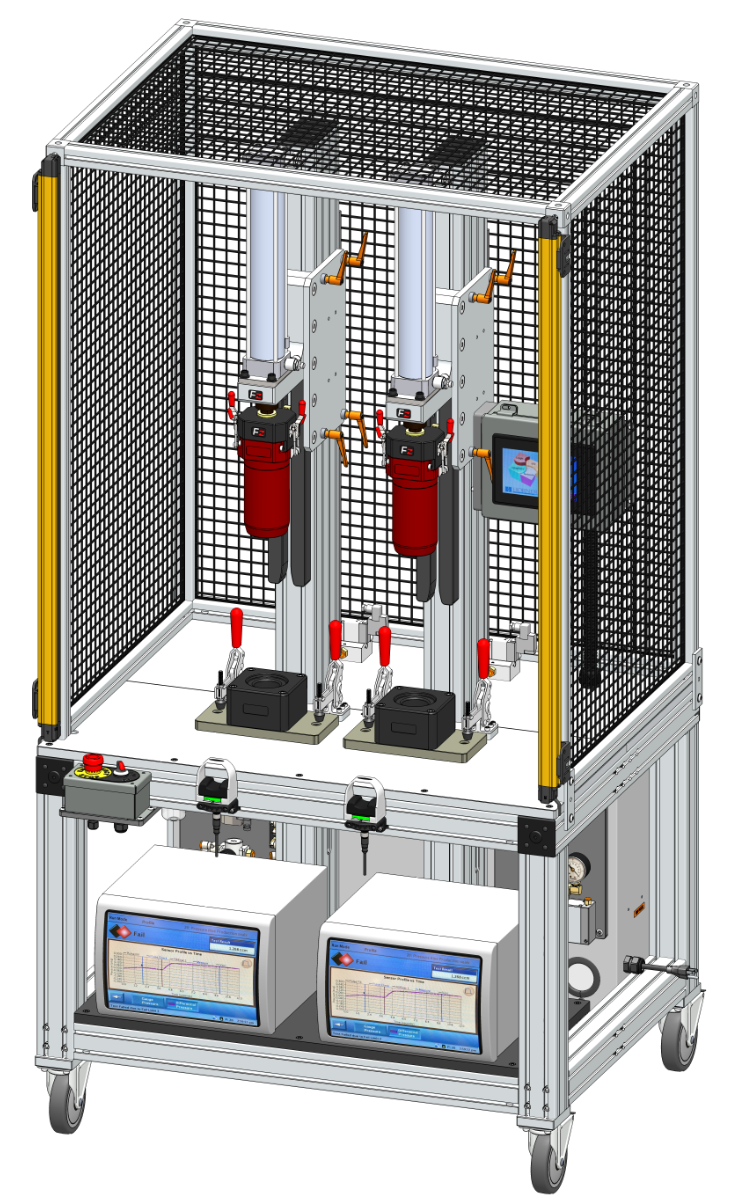

- Helium Vacuum – measurement of outside helium leaking into a part when the part is evacuated using a deep vacuum. Any part leaking allows sprayed outside helium to enter inside the part and gets detected within the vacuum of the helium tester. Helium vacuum is usually the most expensive leak testing method but can find the smallest leaks and is widely used in aerospace and medical applications.

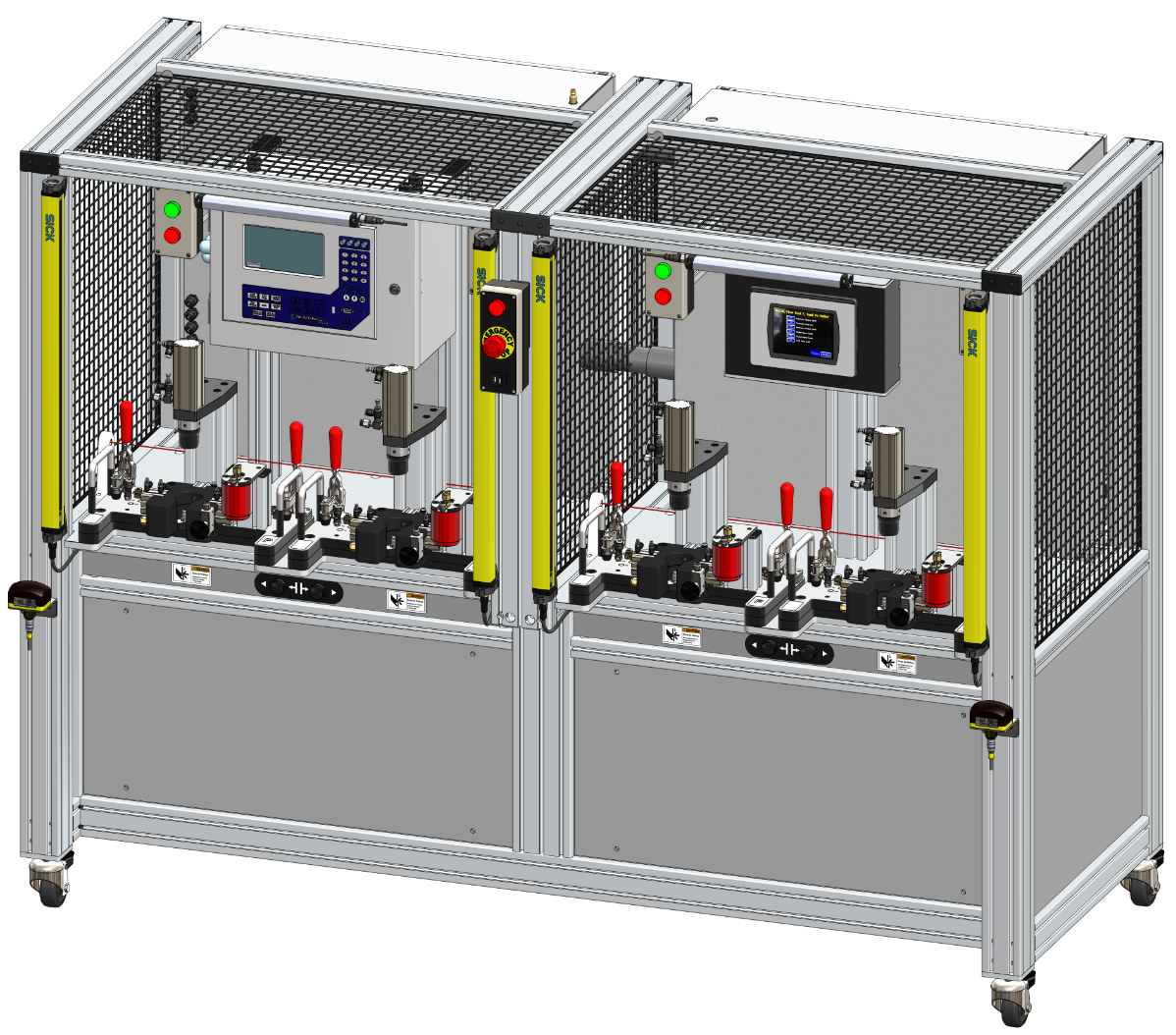

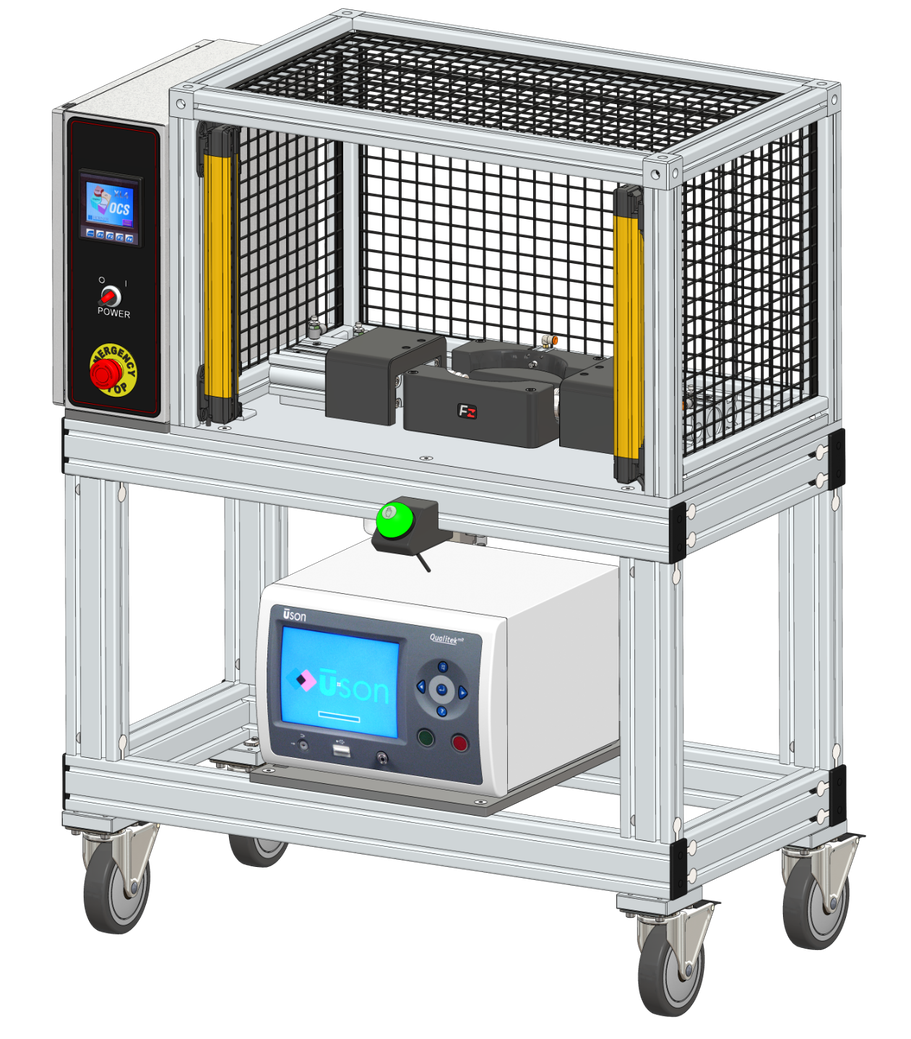

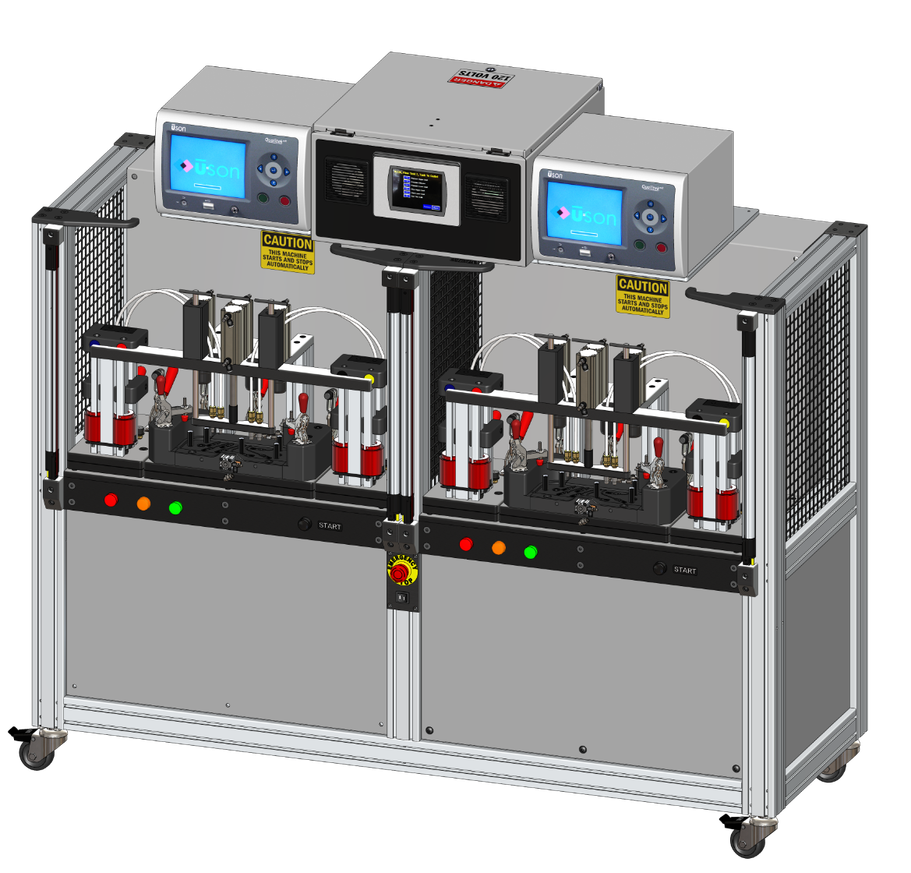

We help our customers select the best testing method and identify a suitable leak tester such as Uson, Cincinnati, Cosmo, Laco etc. We design and manufacture the necessary tooling to fixture and plug the test parts and provide protection for the operator from any moving parts and high pressure. Our testing machines use a PLC to automate the testing and safety processes, provide recipe selection for different fixtures and parts, and mark parts successfully passing the leak test.

Machine Options:

We offer a variety of options to meet the Leak Testing requirements:

- Machine frame, workbench, or table

- Quick-change nests

- Safety cage

- Touch buttons

- Light Curtains

- Barcode reading

- Port sealing

- Test Recipes

- Automatic leak standards

- Pressure Rise Chambers

- Chamber inserts

- Test Pass Marking

- Data Acquisition Test Records

Can we dezein a leak tester for you?

Give us a call or send us an email! We are happy to design and manufacture a piece of test equipment to your exact specifications.