Custom Equipment and Automation:

Fritze Dezein can help you with your special requirements. We thrive on finding solutions for your unique application. Each customer’s special process can have its technology explored and developed by a laboratory test machine or automated to reduce or eliminate manufacturing errors, eliminate repetitive tasks, reduce labor cost, improve worker ergonomics, and provide high-quality manufacturing advantages.

Take a look at some of the many unique custom machines that have helped our customers improve their products and technology.

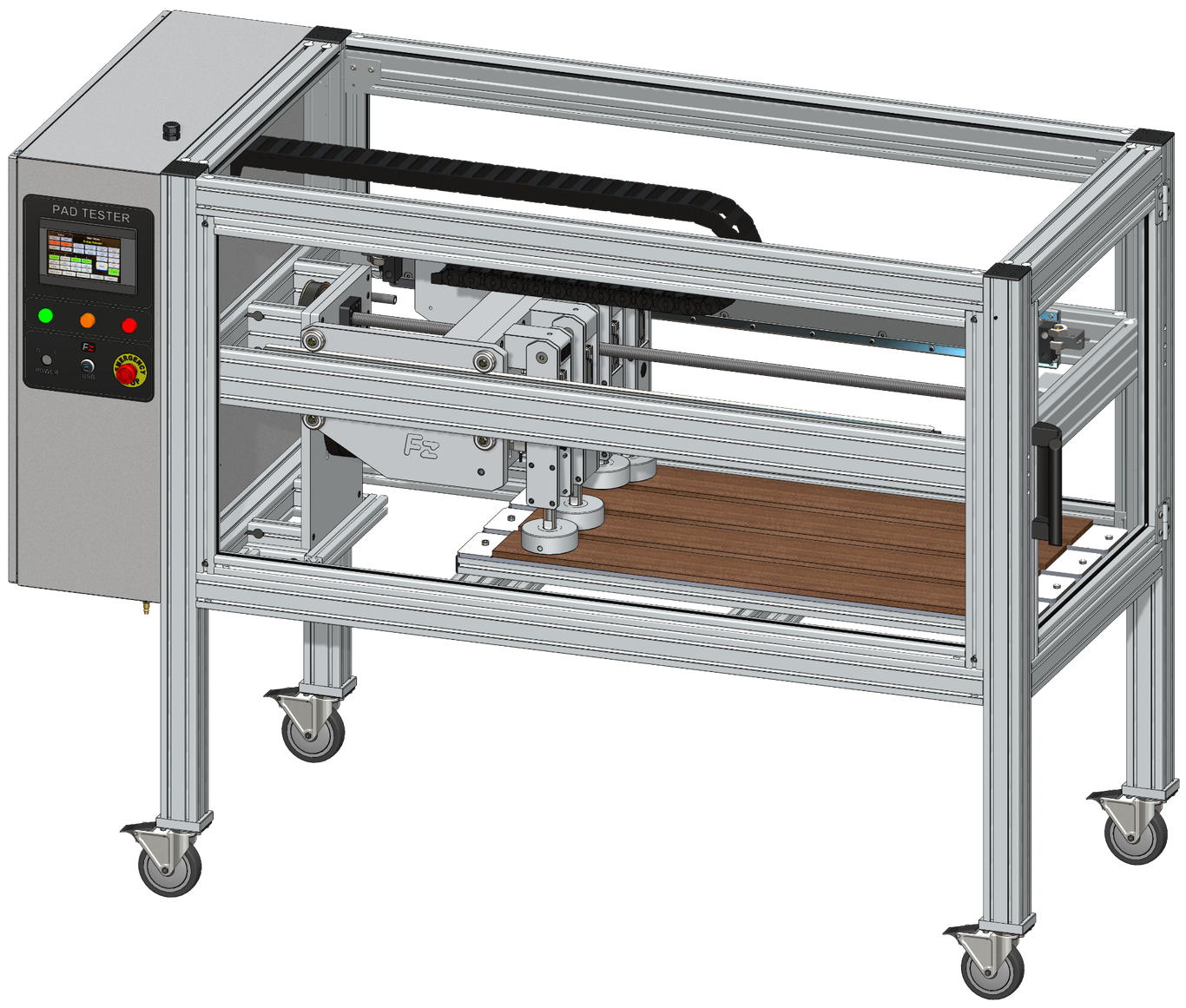

Furniture Glide Tester

An automatic endurance testing machine which subjects four individual furniture glide pads on unique substrates to oscillating sliding forces. Each independent head can alter the pad down force, the pad angle, and track the resulting drag force during the entire test. Fully programmable and able to subject pads to high cycle tests.

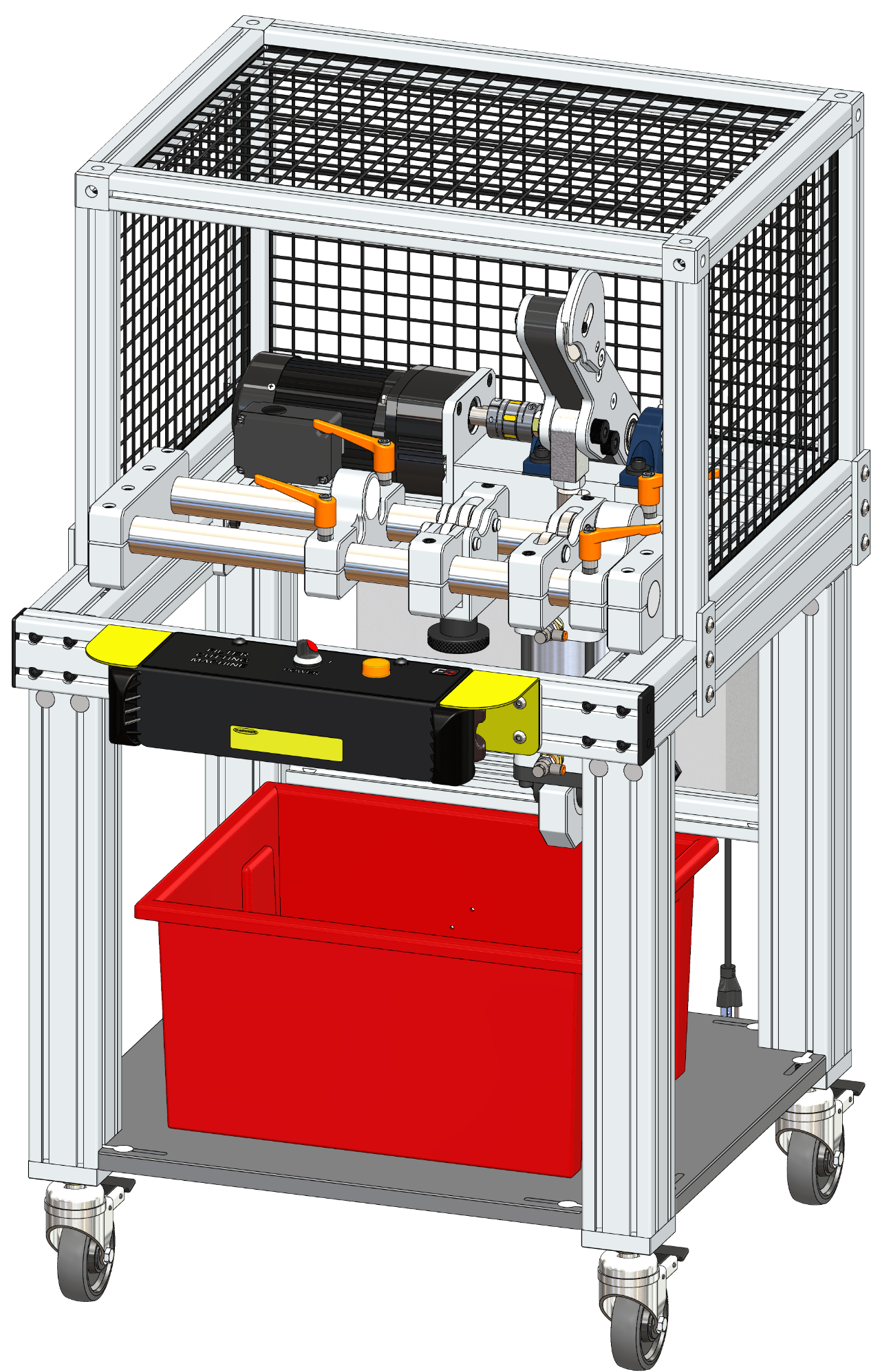

Filter Body Slitting Machine

A powered slitting saw to quickly and carefully dissemble water filter housings to harvest the treatment media inside. Machine can be adjusted for each water filter size and slit location. At a push of a button, an operator can quickly slice a plastic filter in seconds without any mess or affecting the filtration media inside.

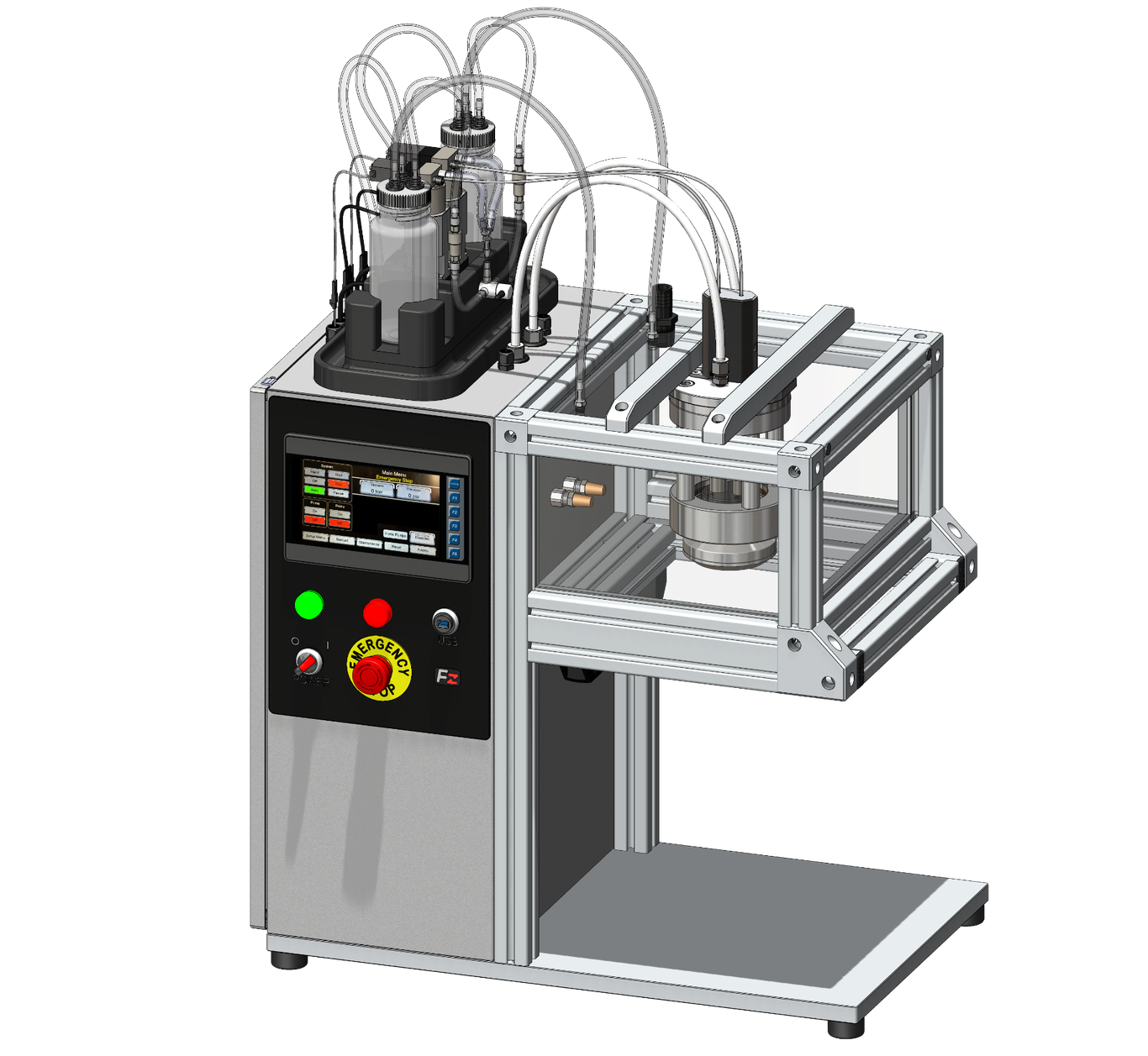

Liquid Infusion Instrument for Research and Development

A research tool to explore the physics of infusing liquid into semi-porous matrixes. The research tool is capable of precision injection of chemical fluids into a chamber subjected to 30 torr of vacuum using a digital micro pump and high-speed injector valves. Research tool chamber can be pressurized to 15.5 atmospheres compressing air bubbles at a ratio of over 390:1. Research tool can operate with a recipe schedule to iteratively infuse liquids to quantify the wetting rate of material matrixes in such uses as electrolyte dispensing.

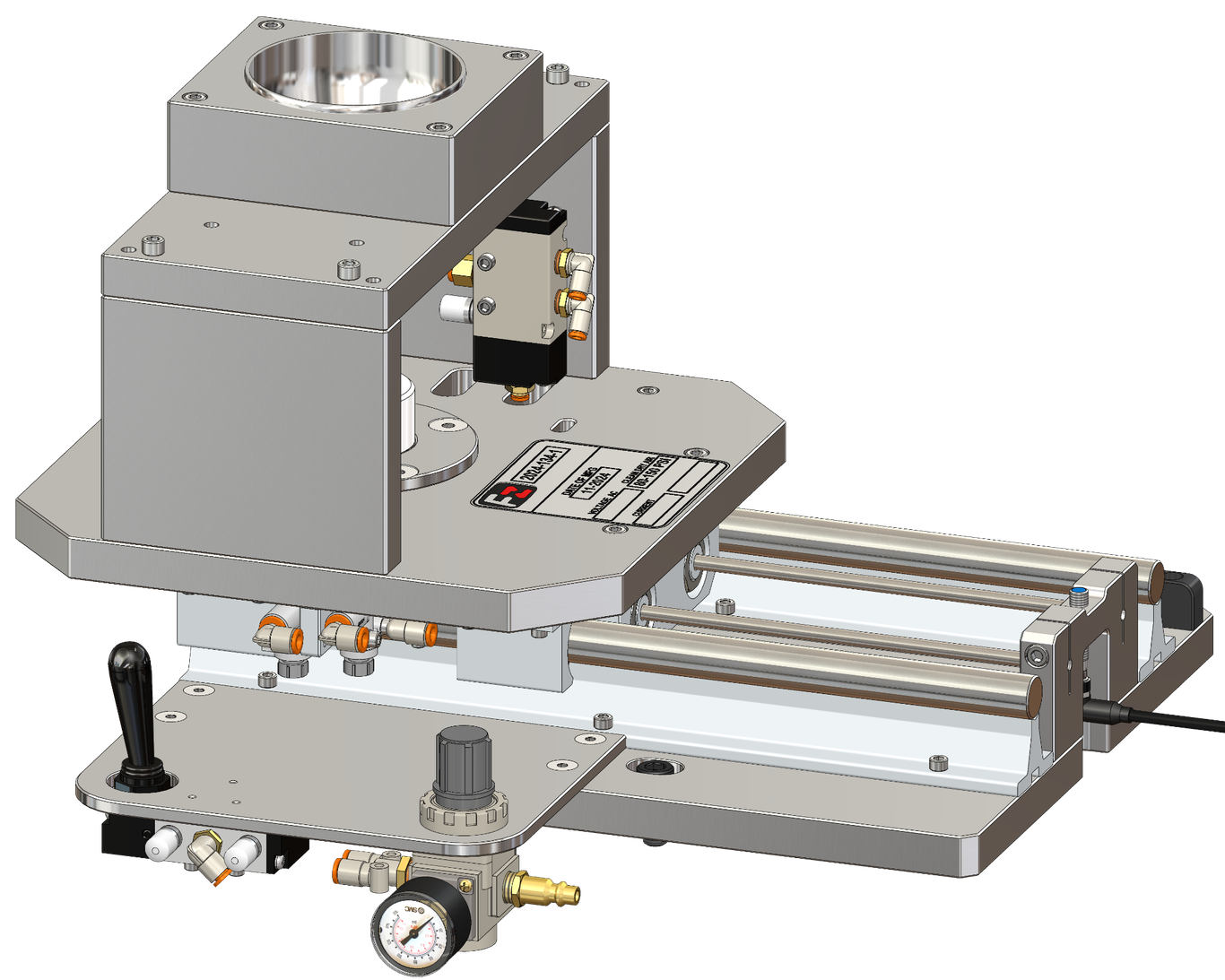

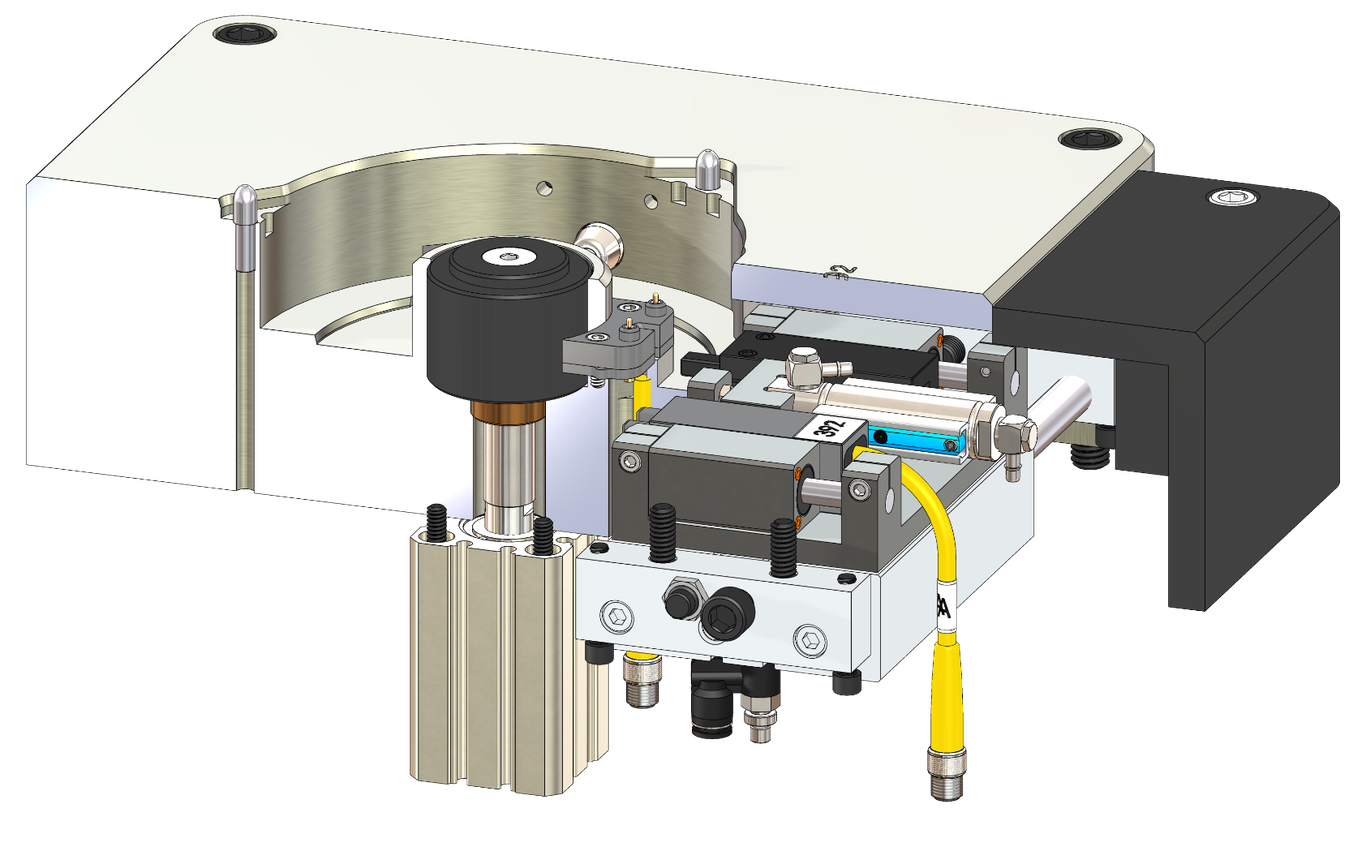

Pneumatic Ultrasonic Weld Fixture

A simple yet robust pneumatic fixture to sonic weld plastic parts. Operator places parts for welding onto fixture and uses a joystick to drive them into precision alignment at the sonic welder. Once the weld is complete, the operator uses the joystick to bring back the welded assembly as it is automatically ejected ready for the next cycle. Fixture reduces operator fatigue, increased safety and ensures a precise fit to achieve perfect welds each time.

Testing Machine for Car Speaker Basket

A production automated electronic tester to verify each plastic insert-molded speaker basket is perfect for its use in robotic production lines of European cars. Each speaker basket is precisely fixtured within a CNC machined nest while various probes and continuity sensors perform quality tests. Each speaker is verified to conform to the exacting standards required by the high-end German marque manufacturer.

Can we dezein a machine for you?

Give us a call or send us an email! We are happy to design and manufacture a piece of assembly equipment to your exact specifications.