Hot-Melt Adhesive Dispensing:

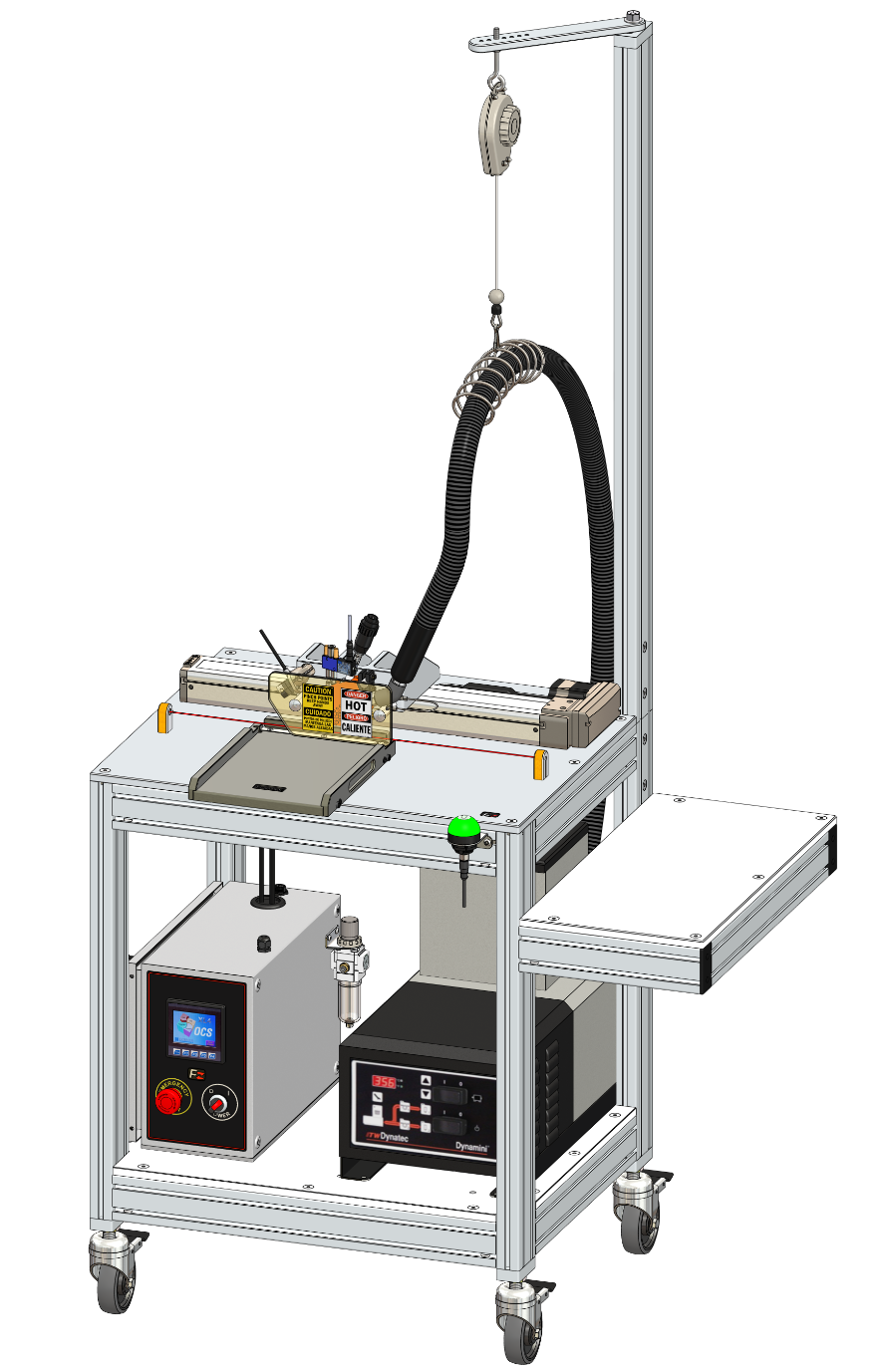

Fritze Dezein builds a variety of custom automated hot-melt glue dispensers by integrating standard hot-melt equipment into automated part handling workstations or conveyor lines. Most of these dispensers fill water filtration components with adhesive while they spin on quick-change nests. Some applications rotate the dispenser head while the parts stay still during application.

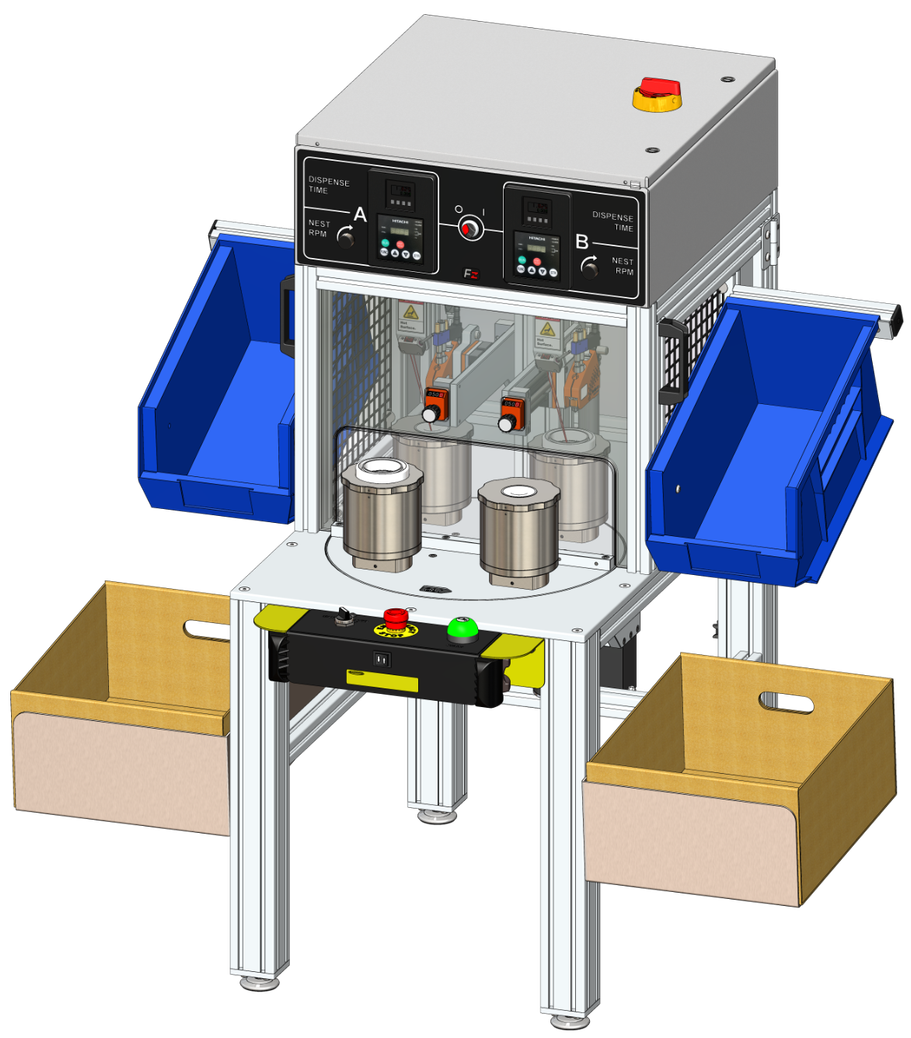

Our standard semi-automatic workstation hot-melt glue dispenser uses a shuttle system that fills one part while the previously filled part is being removed and a new one is installed. We offer many features in our custom designs:

- Variable Speed AC Inverter Motor – The drive system which rotates the nests during adhesive dispensing is an inverter-duty 3-phase motor controlled by a VFD. Rotation speed is per recipe and controls the fill evenly and quietly.

- Pneumatic Rodless Cylinder Shuttle – The shuttle is safely moved left and right each cycle at a set speed for quiet and fast positioning of the carriage. The carriage is magnetically coupled for easy break-away in case of obstruction.

- Twin vertical-adjustable fixtures – Filter elements such as carbon blocks or pleated media can be rapidly located and can even be automatically pressed into the freshly filled adhesive. Magnetically attached fixtures and an acme-screw vertical carriage allows for fast and flexible change-over for different height assemblies.

- Center-protected hot-melt dispensing station – The hot-melt adhesive dispensing head is centrally mounted on an X and Y positioning stages to allow for changes left and right, and in and out as desired per job. Each position is displayed using digital counters locked in position with a screw brake. A pivoting shield protects operator from direct contact with dispenser operation.

- Quick-Change Magnetic Nests – The center drive system rotates each nest as it comes into filling position. The nests are held by a our quarter-turn mag-lok system that allows for a large array of puck fixtures used for your parts. We use a proprietary low-friction corrosion resistant plating on each quick-change nest for easy glue clean-up.

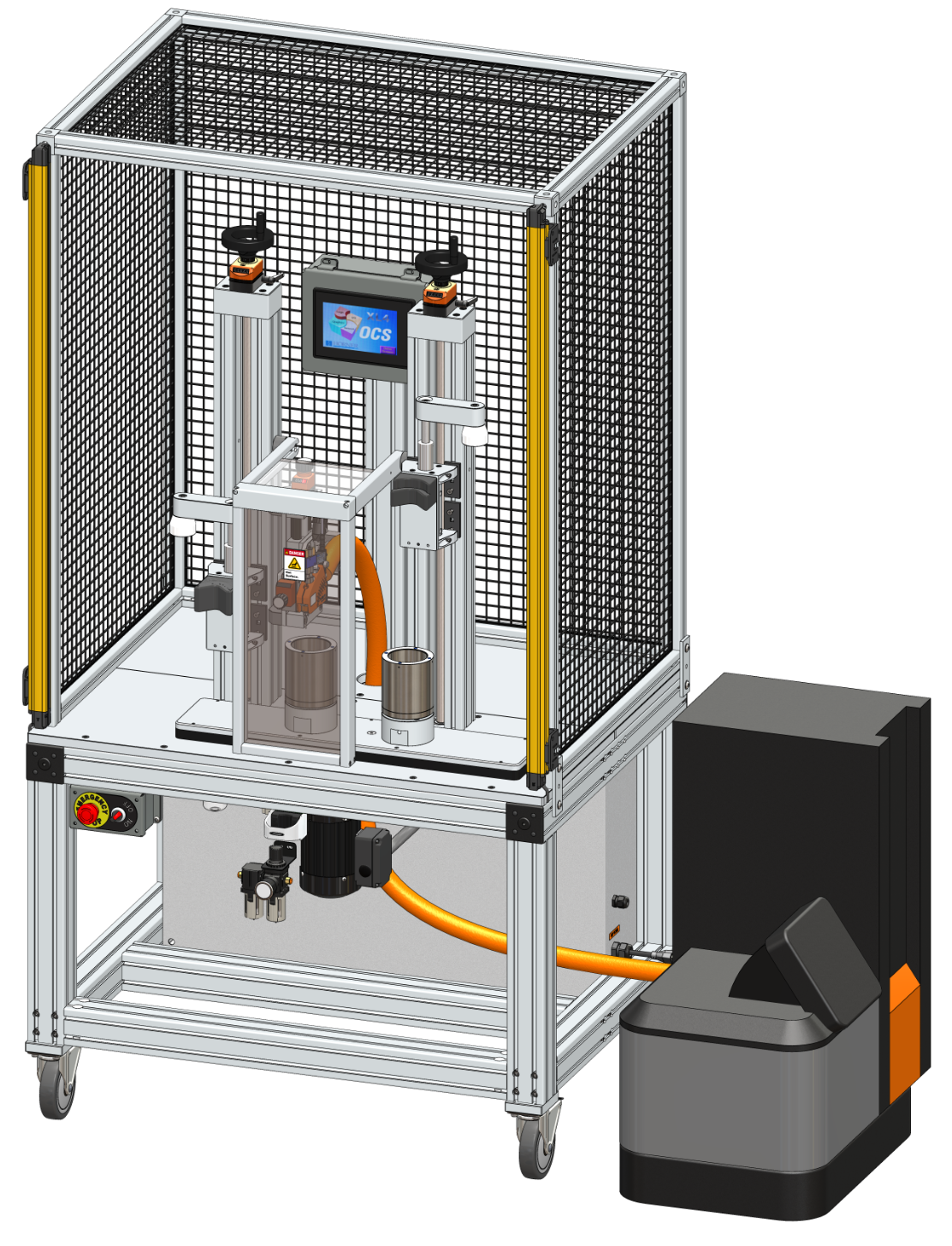

When integrated into a mobile workstation, each hot-melt dispenser is surrounded by a large removable safety cage with light curtains which protect the operator during unsafe conditions. An extruded aluminum frame with a CNC machined aluminum top plate and shuttle provides a platform for our quick-change tooling system. Each job can be configured rapidly by swapping nests and fixtures which are magnetically attached and located in position.

All controls are housed in a spacious rear-mounted metal enclosure.

Our controls are engineered for ergonomic operator use with touch buttons, easy to understand machine status via LED lamp colors, simple touch screen HMI, and fully automated recipe-selected programs.

Our equipment is designed for long service life in harsh environments as we use plastic, aluminum and stainless steel where possible.

Can we dezein a gluing machine for you?

Give us a call or send us an email! We are happy to design and manufacture a piece of assembly equipment to your exact specifications.