Cycle Testing Machines:

Manufactures often need proof that their products exceed NSF/ANSI or other structural performance standards. Production manufactured parts and assemblies often need to be verified that they are capable of remaining operational and leak-proof at their listed maximum pressures for the life of the product. Our cycle testers are used in the laboratory design stage and also during the high-volume manufacture of production lots. Destructive cycle testing subjects an individual part to rigorous pressure pulses for tens of thousands of cycles. We build cycle testers which allow manufactures to test thousands of samples for millions of cycles.

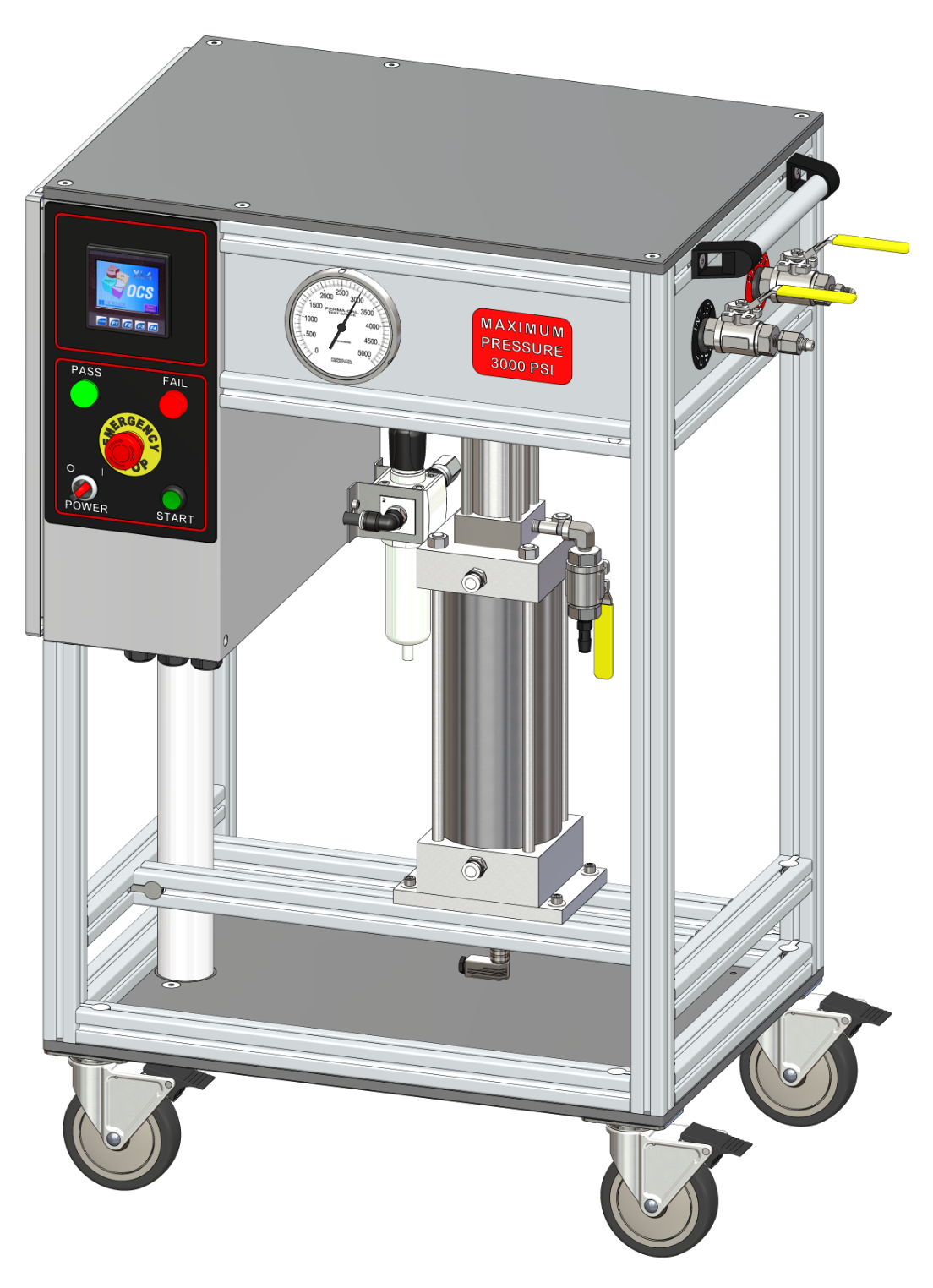

A typical cycle tester uses water to provide a pressure pulse such as 0-150 psi within 2 seconds. Fritze Dezein has pioneered a cycle testing technology which produces a consistent water pressure pulse using a special Pneumatic Hydraulic Intensifier. The Intensifier has the ability to actually measure the exact amount of water used during each pressure cycle, which is used to determine if the parts are passing or failing. Cycle testers with multiple heads can operate un-attended and automatically identify a failed part and isolate it from the rest of the samples under test. Our cycle testers use a closed-loop water circuit while under test to conserve water resources and operate without generating excessive heating. A typical cycle tester can automate the entire testing process with a push of a button to; flush, cycle, identify failures, isolate failed parts, and conclude the test with up to 8 individual test lanes. A 100,000-cycle test according to NSF 42 can usually last 3-days.

Our machines have been is service for decades and are logging 10 million cycles/year. Our cycle testing technology can be used in remote environmental chambers to operate the test parts at high and low temperatures as desired.

Machine Options:

We can offer a variety of options to meet your Cycle Testing requirements:

- Welded plastic enclosure

- Welded Stainless enclosure

- External hose connections

- Quick-change tooling

- Optional locking door

- Illuminated touch buttons

- Barcode reading

- Test Recipes

- Data Acquisition Test Records

- 0-150 psi standard

- 0-3000 psi capable pressures

- Analog or Digital pressure control

Can we dezein a cycle tester for you?

Give us a call or send us an email! We are happy to design and manufacture a piece of test equipment to your exact specifications.