Spin Welder and Cap Threader:

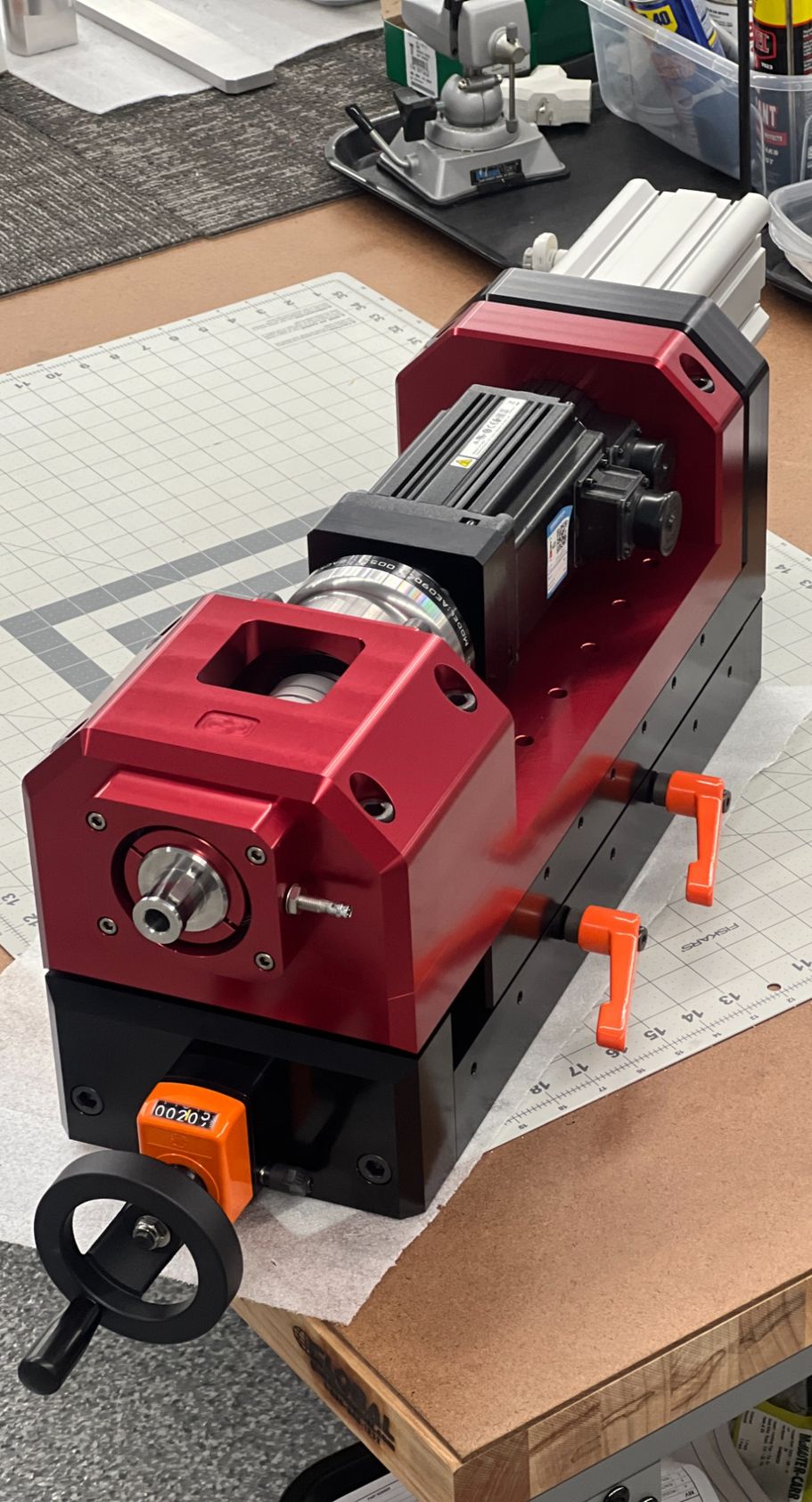

Fritze Dezein builds a heavy-duty servo-driven orientating spin welder head which we use on a variety of applications where manufacturers want high-speed automated operation. Our spin welder is CNC machined from billet aluminum and anodized red and black. We offer many advanced features in our design:

- Servo Motor – The manufacture of the servo motor and drive can be selected to work with many existing PLC platforms including Allen Bradley. Our standard 2KW servo motor system requires 200V-Class 3-Phase and spins up to 5000 rpm with 17.5 n-m torque [66 in-lb].

- Gearbox – We use axial planetary reducers to develop enough torque to weld large parts and hold them precisely until cool. Ratios up to 10:1 are available.

- Vertical Travel – the spin welder head can travel downward 100mm [3.93”] from its home position during each automated cycle.

- Vertical Position Sensor – We use a vertical position sensor that can resolve 5 microns of distance providing precision position information for automated operations.

- Thrust – 100mm bore pneumatic air cylinder provides from 2 to 280 Kg [5-623 lbs.] of automatically controlled down force.

- Linear Bearings – adjustable crossed roller bearings provide very low friction with high rigidity and precision.

- Spindle Bearing – large shielded heavy-duty double-row angular-contact bearings takes the thrust.

- Servo coupler – Zero-Max double-flex servo coupling for maximum orientation precision.

- Vertical Adjustment – The Servo head module can be adjusted via hand-wheel to various height positions for easy job-set-up. An acme lead-screw and a digital indicator provides the welder head with an additional 150mm [6”] of adjustment to allow for repeatable precision job set-ups.

- Gib locks – Spin Welder servo head can be positioned vertically on a dovetail way and saddle with twin hand-knobs which locks the gib in rigid position.

- Electro-Pneumatic Position Control – The Spin Welder head vertical positioning is controlled using a PLC and a pair of electronic air-pressure regulators. Various pressures are applied to move and float the head with different speeds and forces. This electro-pneumatic control allows for gentle or forceful positioning. The vertical position sensor is used to determine part-present or missing, and weld depth control.

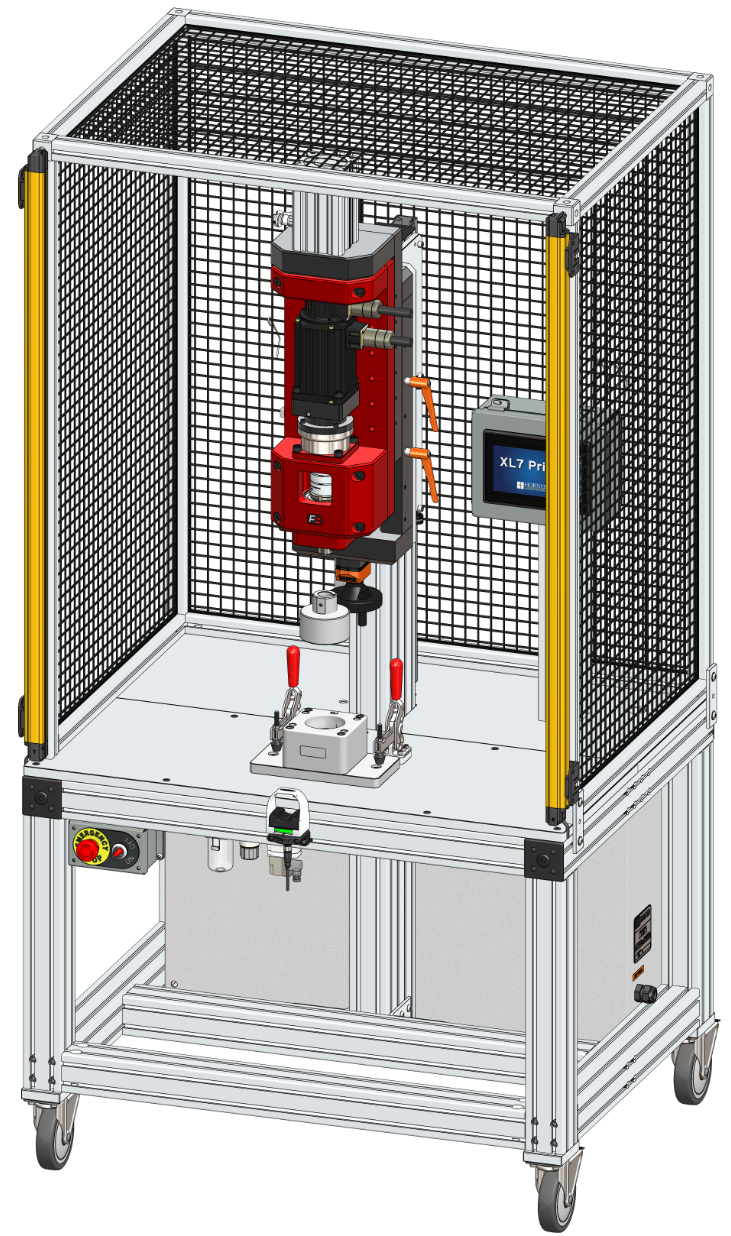

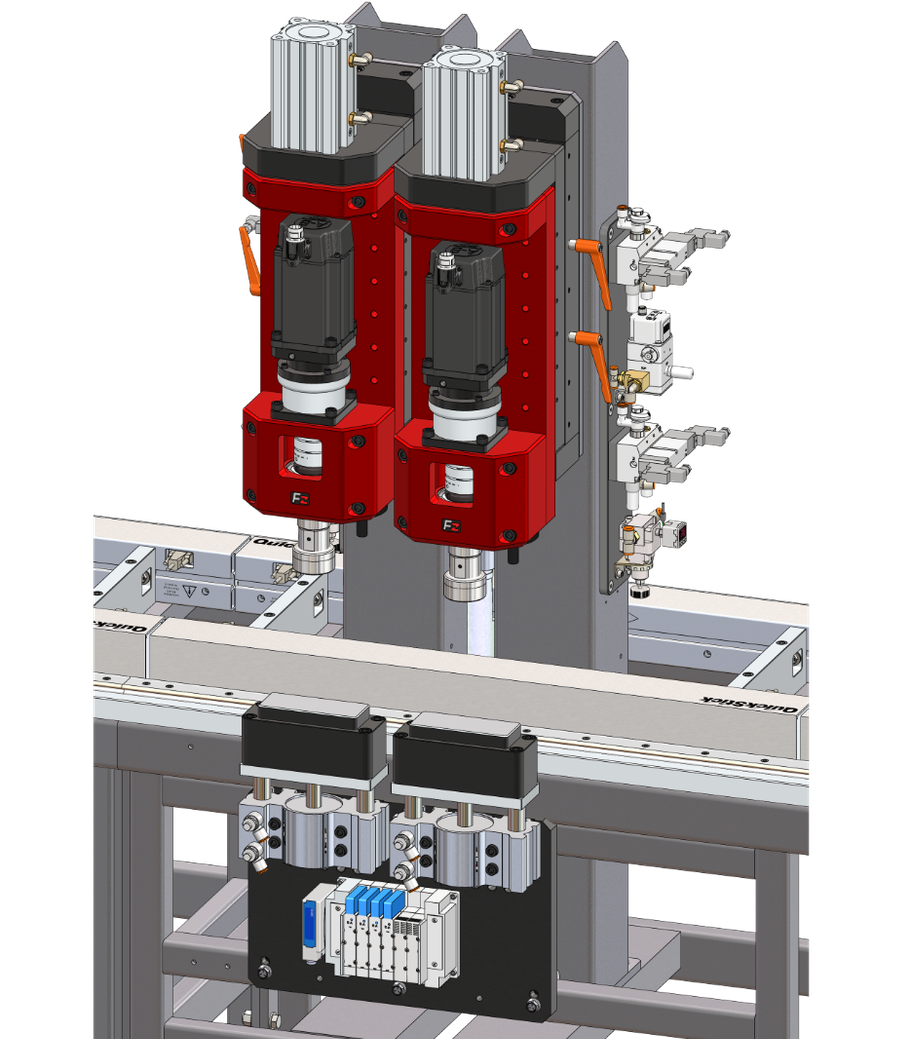

Fritze Dezein integrates it's heavy-duty servo-driven orienting spin welder head into various machine arrangements for production environments. These spin welder heads can be adapted for fully automatic conveyor operations, or can become a fully-protected stand alone machine for semi-automatic operator use.

Our standard spin welder can also be used to precisely thread caps onto bottles or filters as desired. Flexible controls allow for recipe configurations than can be called-up to set the rpm, torque, number of revolutions, starting position, dwell, safe position, and down-force. The spin driver tooling uses a 1” keyed bore and set screws.

When integrated into a mobile workstation, each spin welder head is surrounded by a large removable safety cage with light curtains that protect the operator during unsafe conditions. An extruded aluminum frame with a CNC machined aluminum tooling plate provides a platform for our quick-change tooling system. Each job can be configured rapidly by swapping nests and fixtures which are located by hardened locating pins and secured by toggle clamps.

A massive heavy-duty extruded aluminum column supports the spindle system and various accessories. All controls are housed in a spacious rear-mounted metal enclosure.

Our controls are engineered for ergonomic operator use with touch buttons, easy to understand machine status via LED lamp colors, simple touch screen HMI, and fully automated recipe-selected programs.

Our equipment is designed for long service life in harsh environments as we use aluminum and stainless steel where possible.

Can we dezein a spin welder for you?

Give us a call or send us an email! We are happy to design and manufacture a piece of assembly equipment to your exact specifications.